In logistics, industrial machines are critical for the production throughput of goods and merchandise. Over time, installations and machines become prone to failures. We ensure the optimized operation of your stacker crane or bridge crane installation and other rail-guided industrial vehicles - for increased throughput and energy savings.

By providing sustainable energy savings and by reducing facility wear, PSI Technics optimizes both process costs and maintenance requirements. Improving the mechanical design of your installation through modernizations and replacing inefficient drive or control technology components leads to higher machine availability, material savings and shorter cycle times.

For multiple system applications, harsher environments or when customers choose to turn over support and maintenance to PSI Technics, we can offer custom-tailored on-site services to ensure long-term high availability regardless of the make or model of your installation.

As a first step, PSI Technics analyzes the baseline performance of your machines to determine the potential for optimization and reducing energy consumption. In addition, we evaluate the condition of existing components that could exhibit weak spots in the near future so you can plan ahead to avoid costly disruptions. PSI Technics’ FLP6000MA Motion Analyzing Software provides a comprehensive analysis of the system performance and identifies issues that can impact performance.

In logistics, industrial machines are critical for the production throughput of goods and merchandise. These systems require time-optimized controls to guarantee efficient performance. Machines that require optimization benefit from PSI Technics' Motion Analyzing Software, which enables the analysis of time-related processes as well as the detection and elimination of motion-related weak spots.

The FLP6000MA Motion Analyzing Software was specifically developed for material handling systems and uses the motion profile to identify sources of interference that adversely affect the productivity of your installation.

It enables you to take action to increase the overall process efficiency, such as:

YOUR ADVANTAGE:

Reduced costs and increased throughput

Continue reading

PSI Technics then delivers a comprehensive report that details suggestions for replacing weak system components, considerations for changing machine parameters for improved operation and throughput. The performance analysis results are presented as a time-optimized comparative simulation. An energy consumption analysis that identifies any opportunities to reduce energy usage and cost within the application completes the report.

When it comes to the modernization of existing facilities, PSI Technics places particular emphasis on minimizing downtime. When the modernization is complete, we train your staff in maintenance and troubleshooting, to ensure they are well equipped to respond quickly and resolve any issues.

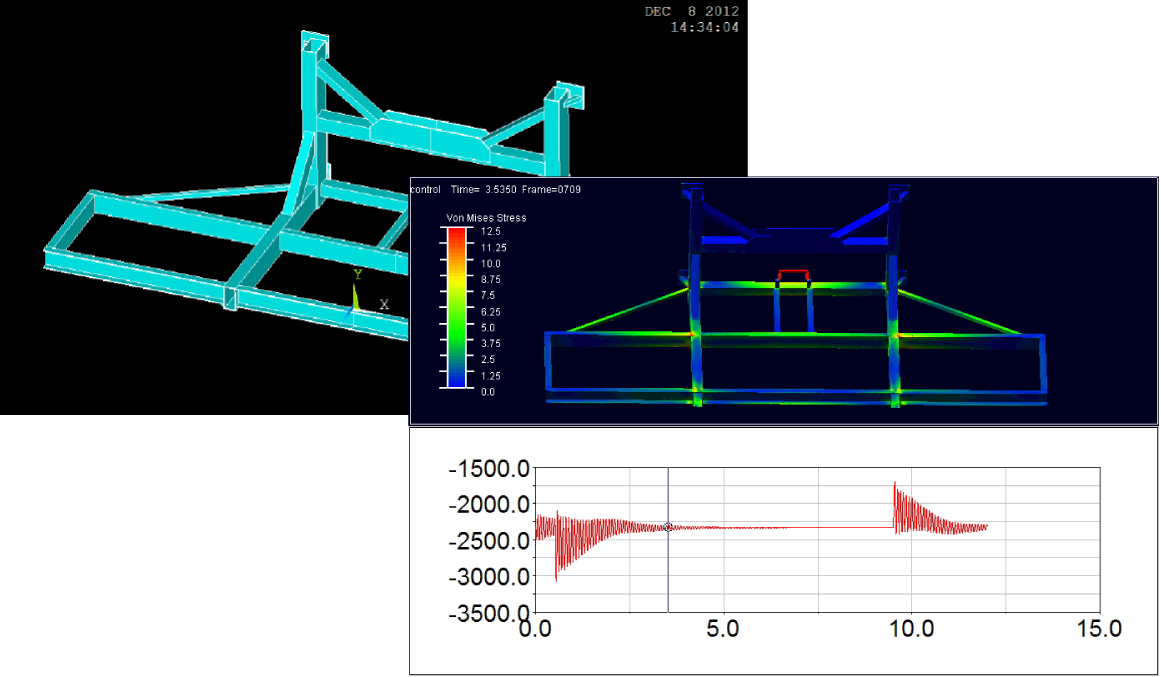

Our Virtual Modeling / Finite Element Method (FEM) is an innovative new service offering that provides you with a "glimpse into the future" of your installation. This service enables you to predict and avoid costly downtimes for new and existing installations, in addition to reducing costs in the long run.

For existing applications, PSI Technics creates computer models to pinpoint stress and strain, weak spots and potential changes for improvement. For new applications, PSI Technics simulates the expected system behavior and performance prior to the actual installation to predict and analytically detect potential interferences.

This approach allows you to identify needed improvements early in the planning stage when comparing designs of different providers.

Talk to us about your requirements - we can provide a solution that is customized to your needs.

support@psi-technics.com

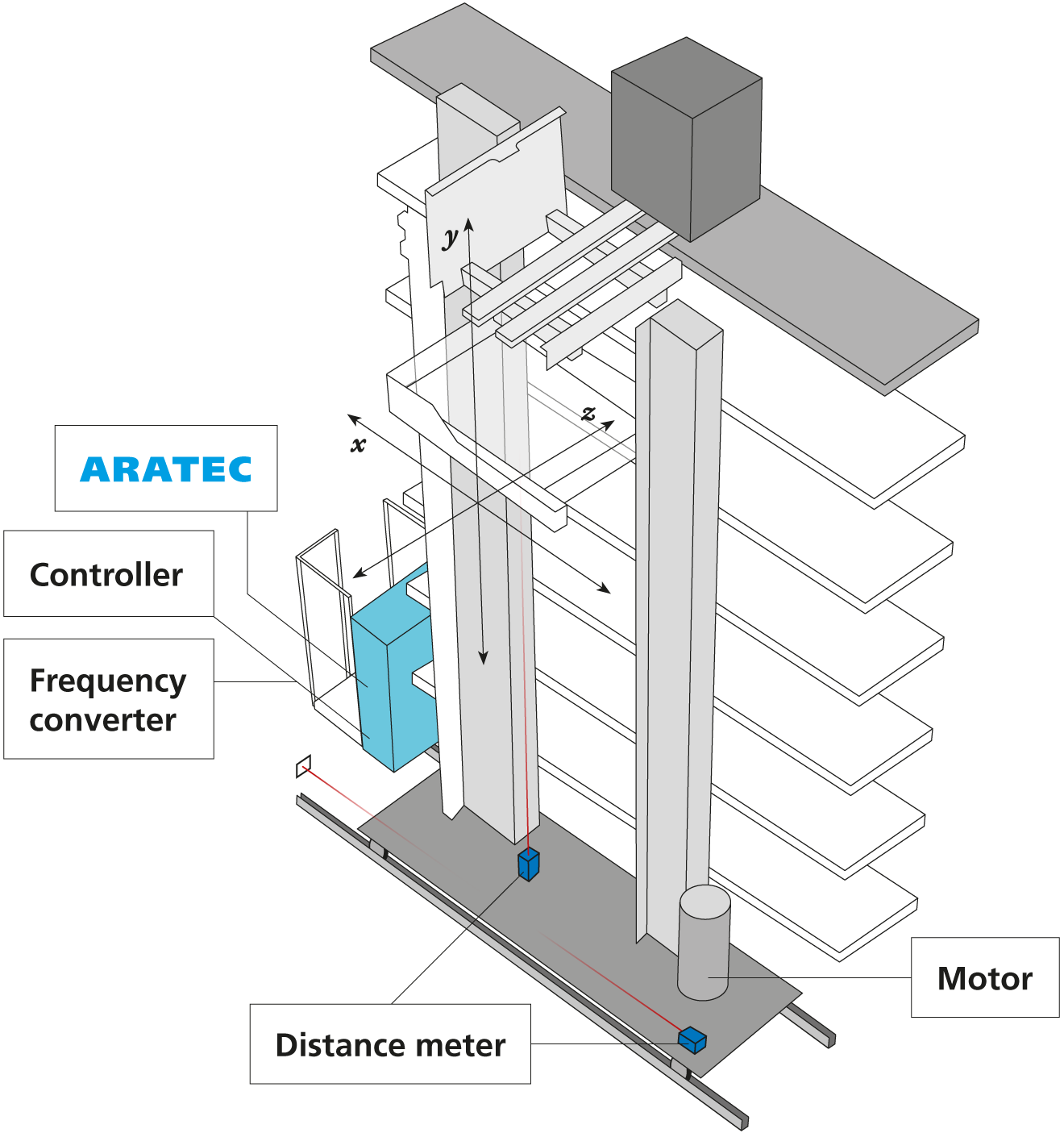

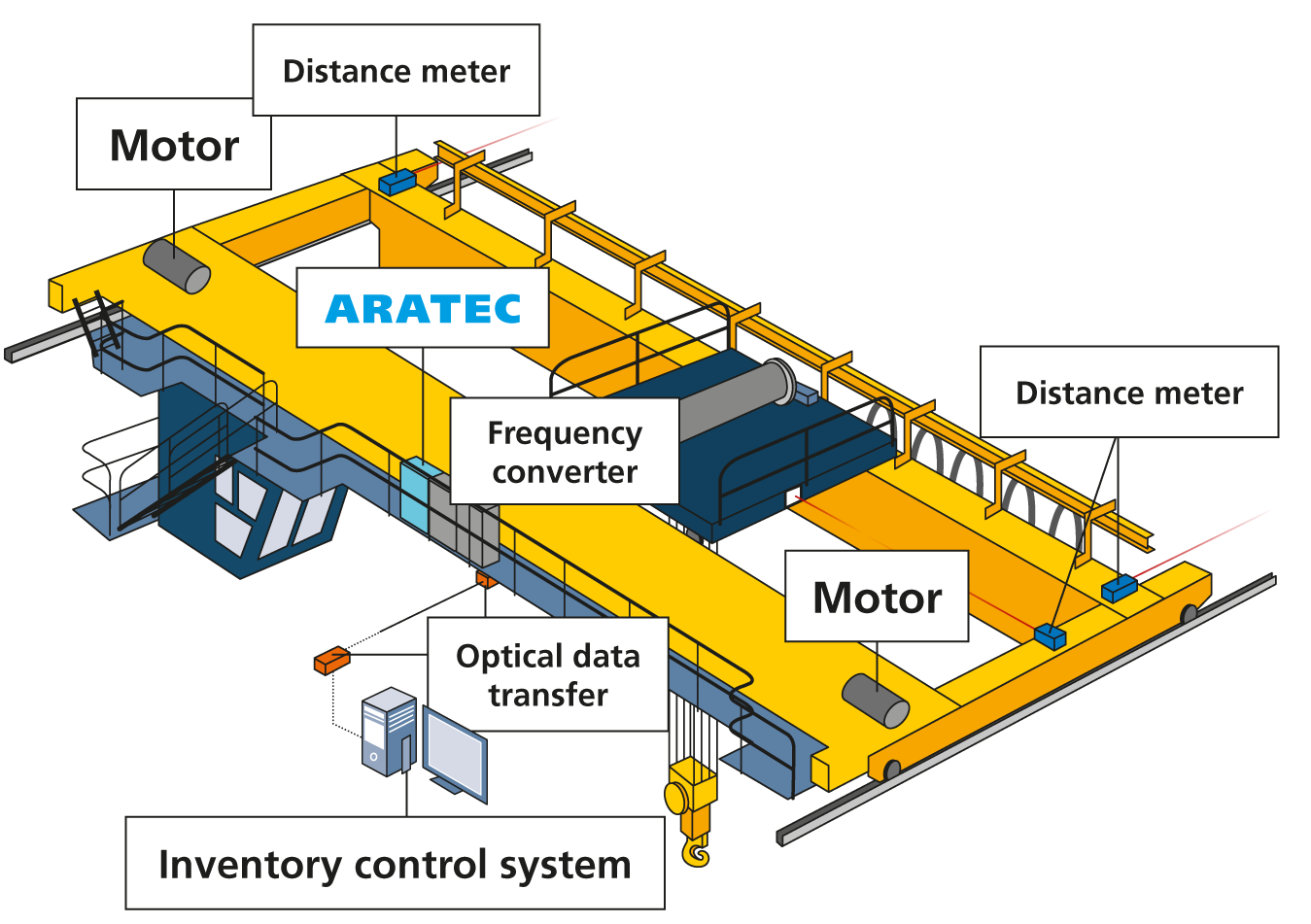

ARATEC Positioning Solution System – Powerful Modernization for Stacker Cranes

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications. In fully automated high-bay warehouses, for example, ARATEC instructs stacker cranes to move to the storage position's target coordinates to ensure that all storage and retrieval operations are carried out with high accuracy in the shortest amount of time. In addition, wear and tear can be reduced to a minimum due to an almost 100% compensation of mast oscillations.

Advantages of the ARATEC:

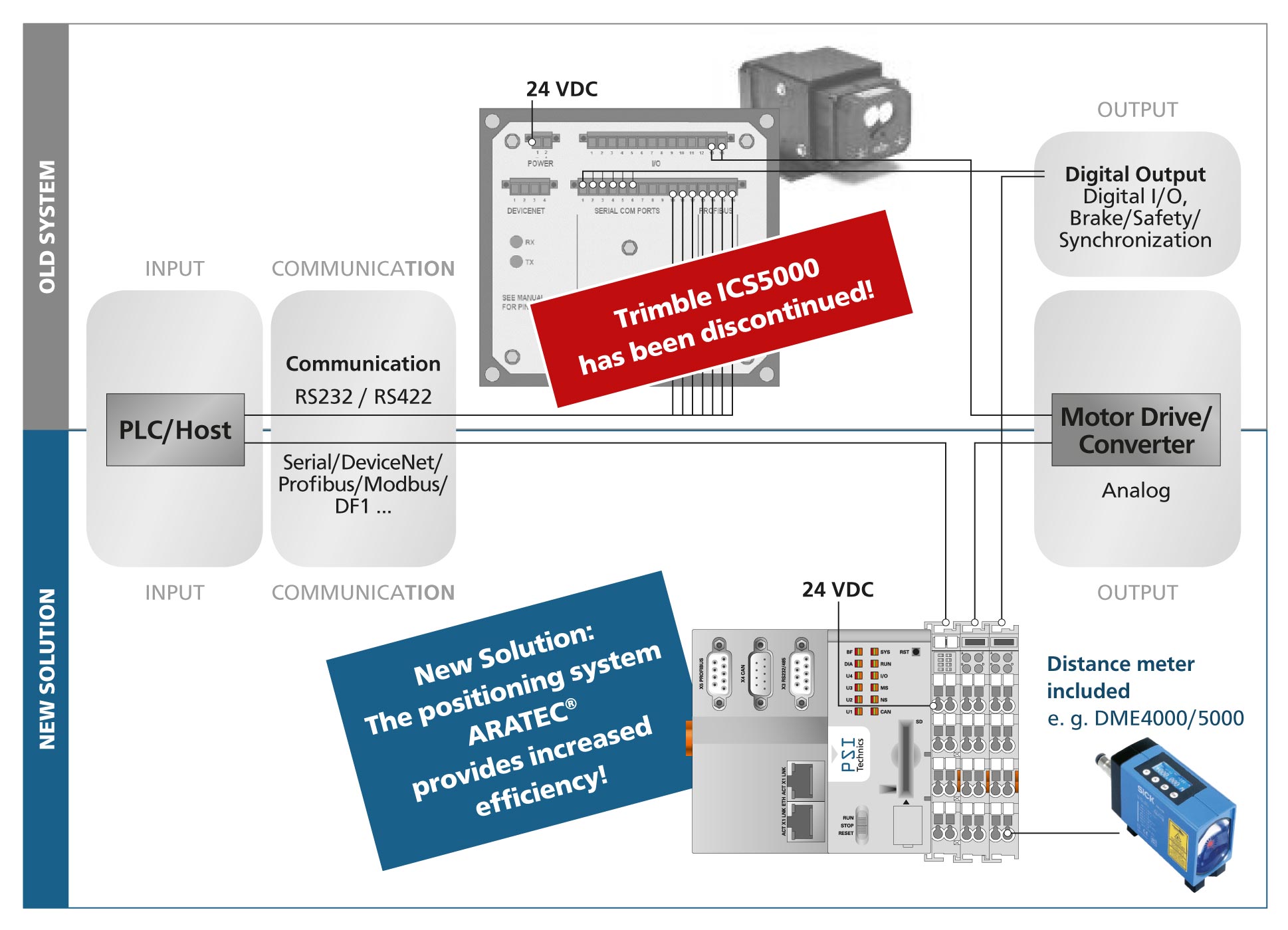

The ICS5000, TCS4000 and ASC positioning systems were discontinued when Trimble closed its Factory Automation department.

To continue to provide users with efficient positioning solutions, PSI Technics developed the ARATEC Positioning Solution System. This positioning system is a fast, easy and budget-conscious replacement for existing installation, such as installations manufactured by Trimble ICS5000L, PLC- or drive-based installations using distance sensors manufactured by SICK, Leuze, Pepperl & Fuchs.

TESTIMONIAL OF TRIMBLE NAVIGATION LTD:

[...]

"If you are planning your upgrade for the ICS units used within your facility, Trimble recommends the ARATEC Positioning Solution System from PSI Technics which was designed specifically to replace the ICS with no changes to PLC or drives, and no programming knowledge required by your staff. The ARATEC Positioning Solution System has many advantages over PLC-based solutions in the market - including providing the capability for your staff to set up and implement the solution to reduce ongoing services costs."

[...]

Complete testimonial

Are you looking for a future-ready positioning system to replace an existing Trimble system? Contact us – our application engineers can provide recommendations for your specific environment. Please call +49 (0) 2630 91590-0 or use the contact form to submit your questions or requests or send an e-mail to support@psi-technics.com.

Thomas Knebel, Maintenance Planner, Automotive Aftermarket, Robert Bosch GmbH, Karlsruhe, Germany:

"PSI Technics' staff is highly qualified and responsive. Due to the system's integration flexibility, we were able to modernize three shuttle cars in the shortest possible time without having to change any system components or drives. The modernization of each shuttle car didn't take longer than half a day.

Apart from the easy installation, we were so impressed with the increased efficiency of the new system that we already ordered ten additional ARATEC systems that are not only going to replace older systems but will also be used for new installations."

Continue reading

The positioning system ARATEC is a fast, easy and budget-conscious replacement for existing Trimble installations (ICS5000, TCS4000 and ASC). The system interface is compatible with existing Trimble devices, and there is no need for replacing existing controllers. It even works with existing communication protocols, I/O signals and analog set point values for motor drives. System integration requires no complex process control modifications or modifications to connected system components.

The ARATEC Positioning Solution System Advantages:

Marc Valkeneers, Technical Coordinator, SKF Tongeren, Belgium:

"We depended on the Trimble TCS4000 since 1995. When we heard that the production was to be discontinued, we needed to ensure the future of our warehouse logistics. We wanted to guarantee the smooth operation of our facilities and a continued spare parts supply for our customers. This was how the long-lasting cooperation between SKF and PSI Technics started.

Due to the modular design of the positioning system ARATEC we were able to distribute the costs and to gradually modernize the stacker cranes in our high-bay warehouse. ARATEC completely replaced the previously used Trimble TCS4000 units – without the need to replace existing system components or drives. Based on the system‘s machine modeling, we were able to improve our motion path efficiency."

PSI Technics' ARATEC Positioning Solution System is more than a suitable replacement for the existing Trimble installations ICS5000, TCS4000 and ASC. Unlike Trimble systems, it uses a separate distance meter and a separate digital host, which is able to simultaneously control several axes (x/y/z). Its modular design allows for flexible installation and integration into existing systems without incurring undue expenses. In addition, users can benefit from the numerous advantages the innovative ARATEC Positioning Solution System has to offer.

The positioning software is called FLP6000MC. The abbreviation FLP stands for "Fast Loop Positioning". The FLP6000MC software is controlled by a microcomputer and runs on an advanced, powerful and extremely fast industrial PC.

ARATEC® TPCC® - Registered in U.S. Patent and Trademark Office

Understand. Challenge the status quo. Consistently move forward: This is our vision of progress. We are advancing digitalization and we are leveraging existing data to create added value for our customers.

AUTOMATE. OPTIMIZE. INCREASE QUALITY. SAVE ENERGY.

Immerse yourself in the world of PSI Technics, the competence center for digitalization and automation. We accompany your technical and industrial processes into the future.

You can also use our contact form to make an appointment for an individually guided tour. Click here to visit our digital showroom

From March 21, 2022, you will find us at our new address An der Steinkaul 6a, 56333 Winningen in the industrial and business park "Am Flugplatz". Watch the highlights of the new company building

As image processing experts, we develop custom system solutions for challenging processes, e. g. for the Food Industry - Watch movie for Railway Transport and Logistics - Watch movie for the Automotive Industry - Watch movie for the Raw Materials / Commodities Industry - Watch movie

Designed for the continuous monitoring and visual quality control of production processes.

PSI Technics offers easy-to-use, application-specific digital image processing solutions that are designed for the continuous monitoring and quality control of production processes. Nearly all monitoring and measuring tasks can be automated by means of industrial image processing. Watch movie

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.Watch movie

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market: For STACKER CRANE applicationsFor BRIDGE CRANE applications

PSI Technics' ARATEC Positioning Solution System is an innovative and advanced solution for industrial positioning applications. Watch movie

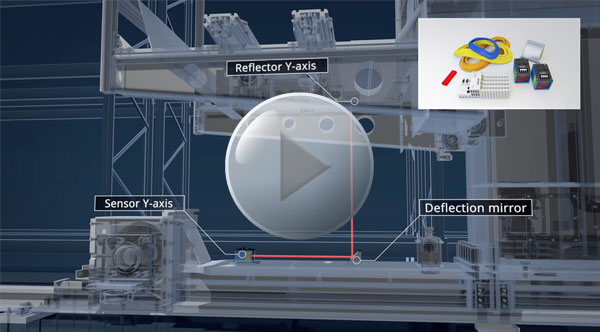

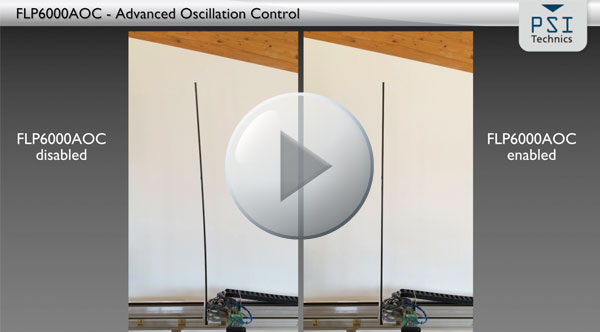

The ARATEC's FLP6000AOC software reduces mast oscillations – even of highly dynamic stacker cranes – to a minimum. The test setup shows that the ARATEC Positioning Solution System with enabled FLP6000AOC compensates for mast oscillations in near-real time, even when the oscillations are caused by external disturbances.

You've got questions, requests or comments about our products and services? Contact our service team and receive a non-binding consultation.

PSI Technics GmbH

An der Steinkaul 6a

56333 Winningen | Germany

PHONE +49 (0) 2630 91590-0

FAX +49 (0) 2630 91590-99

info@psi-technics.com