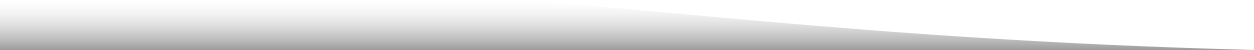

From automated visual inspection and data analysis to maintenance optimization through artificial intelligence – PSI Technics offers a sustainable and advanced rolling stock maintenance solution.

(QuickStart: A simplified sensor portal that starts collecting digital train data at the onset of each project to ensure that relevant data is taken into account throughout the course of the project, e. g., for creating artificial intelligence models.)

Since the inspection takes place when the train passes through tunnel, the railway maintenance shop is freed up for other maintenance-related tasks. Trains that do not need to be serviced remain operational, which increases maintenance efficiency and sustainability and improves the availability and timeliness of trains while ensuring process reliability.

The inspection tunnel combines three vital elements of automated train inspection:

To provide customers with a condition-based maintenance solution for the visual inspection of rail vehicles, our engineers developed an automated camera-based system. The system records all damages or anomalies to the wearing strips, roof, sides and the underbody of any train that passes it, for example, when the train enters a depot or drives through a dedicated "inspection tunnel". The recorded data is send directly to the Analytics software module. After the images have been analyzed by the Analytics software, the inspection reports are created automatically and can be viewed directly via an intuitive user interface. The analysis results are repeatable, reliable and immediately available.

Artificial Intelligence (AI) - Data Mining - Deep Learning - Machine Learning

Artificial intelligence algorithms enable camera systems to learn from samples. Based on large volumes of recorded and analyzed data, modern machine learning algorithms help to continuously improve the evaluation of quality-related properties. The obtained data can subsequently be used for further processing and analysis.

The more data is collected, the better the software "learns" to interpret potential correlations. It intelligently and automatically combines recorded data to generate additional information for every train or component, saving valuable time and ensuring precise maintenance planning.

The results of the automated train inspection are stored in the cloud, to ensure that data from various systems at different locations can be shared and used simultaneously. Detecting wear and tear at an early stage contributes to the optimization of rolling stock maintenance processes and ensures the continuous and seamless monitoring of safety-critical components.

VIDEO: Industrial Image Processing for Railway Transport and Logistics

Our application experts are standing by to answer your calls or written requests. Please call +49 (0) 2630 91590-0 or use the contact form to submit your queries or send an email to support@psi-technics.com

Image Source: PSI Technics, Inodo, Optikon, AdobeStock

Understand. Challenge the status quo. Consistently move forward: This is our vision of progress. We are advancing digitalization and we are leveraging existing data to create added value for our customers.

AUTOMATE. OPTIMIZE. INCREASE QUALITY. SAVE ENERGY.

Immerse yourself in the world of PSI Technics, the competence center for digitalization and automation. We accompany your technical and industrial processes into the future.

You can also use our contact form to make an appointment for an individually guided tour. Click here to visit our digital showroom

From March 21, 2022, you will find us at our new address An der Steinkaul 6a, 56333 Winningen in the industrial and business park "Am Flugplatz". Watch the highlights of the new company building

As image processing experts, we develop custom system solutions for challenging processes, e. g. for the Food Industry - Watch movie for Railway Transport and Logistics - Watch movie for the Automotive Industry - Watch movie for the Raw Materials / Commodities Industry - Watch movie

Designed for the continuous monitoring and visual quality control of production processes.

PSI Technics offers easy-to-use, application-specific digital image processing solutions that are designed for the continuous monitoring and quality control of production processes. Nearly all monitoring and measuring tasks can be automated by means of industrial image processing. Watch movie

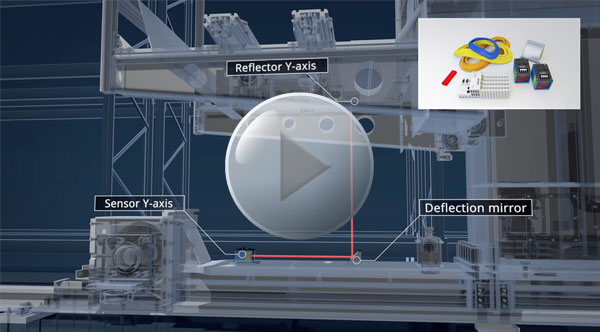

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.Watch movie

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market: For STACKER CRANE applicationsFor BRIDGE CRANE applications

PSI Technics' ARATEC Positioning Solution System is an innovative and advanced solution for industrial positioning applications. Watch movie

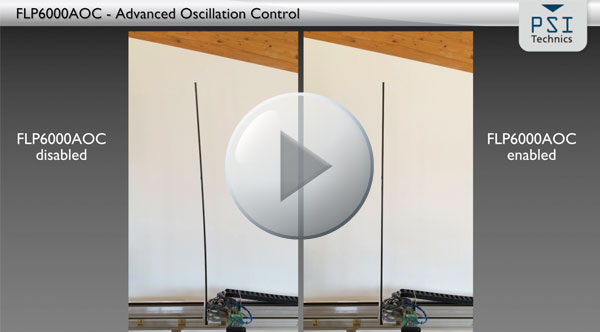

The ARATEC's FLP6000AOC software reduces mast oscillations – even of highly dynamic stacker cranes – to a minimum. The test setup shows that the ARATEC Positioning Solution System with enabled FLP6000AOC compensates for mast oscillations in near-real time, even when the oscillations are caused by external disturbances.

You've got questions, requests or comments about our products and services? Contact our service team and receive a non-binding consultation.

PSI Technics GmbH

An der Steinkaul 6a

56333 Winningen | Germany

PHONE +49 (0) 2630 91590-0

FAX +49 (0) 2630 91590-99

info@psi-technics.com