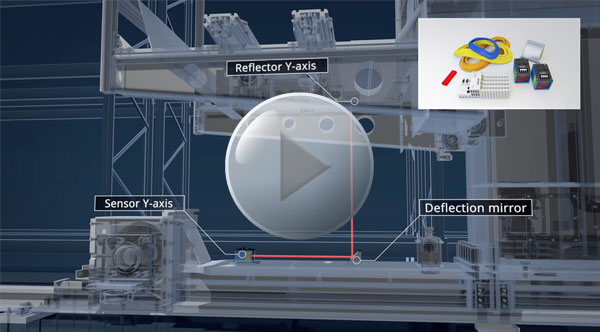

The module enables two independently driven bridge cranes to operate in tandem. Using this method two cranes or trolleys can transport certain goods like a single machine and the permissible skew is freely configurable.

Excellent Reliability, Optimum Travel Profile and Minimum Wear

Production and warehousing facilities usually have a parallel layout where multiple conveyor systems are installed side by side. The cranes operate independently of each other within their particular workspace and the dimension of transported goods is limited to this working space. Cranes that are transporting long goods, for instance, can quickly reach the available space limits as well as their rated load capacity.

OPTIONAL ADD-ON FOR THE ARATEC POSITIONING SOLUTION SYSTEM

Travel profile of a system configured for tandem operation.

Travel profile of a system configured for tandem operation.During regular operation, cranes travel independently of each other. With the ARATEC Positioning Solution System from PSI Technics, two cranes can now be coupled to operate in tandem mode for the transport of unusually dimensioned goods or loads that exceed the cranes' rated capacity. ARATEC couples the cranes automatically by squaring both machines, driving them to identical positions. Once coupled, the cranes move in tandem, while simultaneously compensating for certain irregularities, such as those due to mechanical differences like slightly different travelling wheels, motors or drives. Once the positioning task has been completed, the system can be switched back to regular operation as needed.

Option 3, Master mode:

The master crane moves to the position of the subordinate crane.

Option 2, Subordinate mode:

The subordinate crane moves to the position of the master crane.

Option 1, Master-Subordinate mode:

Both cranes move to a predefined position.

Our application engineers would be happy to provide recommendations for your specific operating environment. Please call +49 (0) 2630 91590-0 or use the contact form to submit your questions or requests or send an e-mail to support@psi-technics.com.

ARATEC® TPCC® - Registered in U.S. Patent and Trademark Office

Understand. Challenge the status quo. Consistently move forward: This is our vision of progress. We are advancing digitalization and we are leveraging existing data to create added value for our customers.

AUTOMATE. OPTIMIZE. INCREASE QUALITY. SAVE ENERGY.

Immerse yourself in the world of PSI Technics, the competence center for digitalization and automation. We accompany your technical and industrial processes into the future.

You can also use our contact form to make an appointment for an individually guided tour. Click here to visit our digital showroom

From March 21, 2022, you will find us at our new address An der Steinkaul 6a, 56333 Winningen in the industrial and business park "Am Flugplatz". Watch the highlights of the new company building

As image processing experts, we develop custom system solutions for challenging processes, e. g. for the Food Industry - Watch movie for Railway Transport and Logistics - Watch movie for the Automotive Industry - Watch movie for the Raw Materials / Commodities Industry - Watch movie

Designed for the continuous monitoring and visual quality control of production processes.

PSI Technics offers easy-to-use, application-specific digital image processing solutions that are designed for the continuous monitoring and quality control of production processes. Nearly all monitoring and measuring tasks can be automated by means of industrial image processing. Watch movie

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.Watch movie

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market: For STACKER CRANE applicationsFor BRIDGE CRANE applications

PSI Technics' ARATEC Positioning Solution System is an innovative and advanced solution for industrial positioning applications. Watch movie

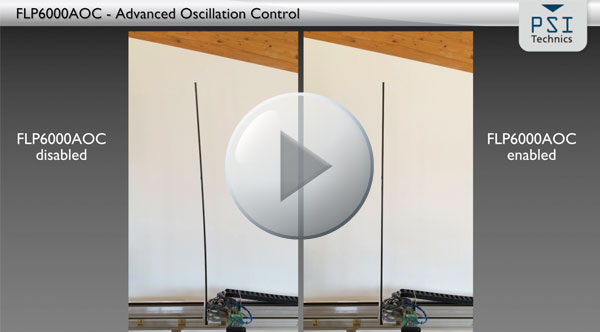

The ARATEC's FLP6000AOC software reduces mast oscillations – even of highly dynamic stacker cranes – to a minimum. The test setup shows that the ARATEC Positioning Solution System with enabled FLP6000AOC compensates for mast oscillations in near-real time, even when the oscillations are caused by external disturbances.

You've got questions, requests or comments about our products and services? Contact our service team and receive a non-binding consultation.

PSI Technics GmbH

An der Steinkaul 6a

56333 Winningen | Germany

PHONE +49 (0) 2630 91590-0

FAX +49 (0) 2630 91590-99

info@psi-technics.com