Virtual modeling (also known as "finite element analysis") is part of our custom service portfolio To date, renowned companies successfully rely on this service offering to achieve substantial improvements in cycle times, energy conservation, reliability and facility lifespan. We empower customers to fully utilize the hidden potential of positioning technology to achieve tangible results. For additional information about this service offering or supplementary case studies, please contact us at support@psi-technics.com.

Advanced Planning: PSI Technics' use of sophisticated Virtual Models / Finite Element Methods helps detect potential weaknesses that can affect future performance. Using virtual modeling, PSI Technics offers you a "glimpse into the future" of your installation. This service enables you to predict and avoid problems that can lead to costly downtimes in new and existing installations, in addition to cutting costs in the long run.

For existing applications, PSI Technics creates computer models to pinpoint stress and strain, weak spots and potential changes for improvement.

For new applications, PSI Technics simulates the expected system behavior and performance prior to the actual installation to predict and analytically detect potential interferences. This approach allows you to identify needed improvements early in the planning stage when comparing designs of different providers.

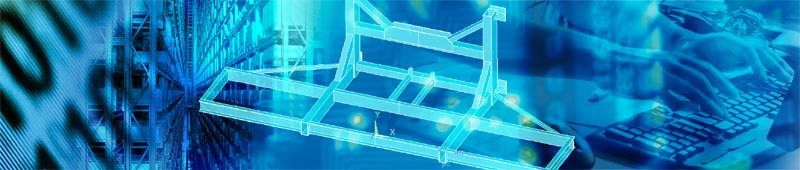

The Volkswagen AG Conveyor Technology Planning department (PWG-P/F) commissioned PSI Technics to analyze and evaluate a vertical material lift in a vehicle body warehouse. The successful cooperation was aimed at developing a new positioning standard for similar vertical lifting systems.

Virtual modeling – an analysis of machine behavior via computer modeling – was used to simulate all relevant system components and to digitally recreate a variety of different loading conditions. Volkswagen's goal was to reveal optimization potential with regard to improving cycle times, system stability and reduced wear.

Virtual modeling provides reliable data and extensive insights into machine behavior.

By using virtual modeling, different drive and closed-loop configurations could be compared and evaluated with regard to their cost-benefit ratio prior to retrofitting the XSB51 vertical material lift. Based on Volkswagen AG's positive experiences with PSI Technics' ARATEC Positioning Solution System at their Wolfsburg factory, the ARATEC was also used for the virtual modeling pilot project.

Revealing and realizing optimization potential.

A motion analysis was performed to determine the system's current motion profile, which provided a basis for identifying optimization potential. All existing loading conditions and motion sequences were simulated in a virtual model using finite element methods (FEM), multi-body models and controller modeling. FEM is an accepted method of obtaining detailed analysis data. The results were verified against the actual operation of the system and illustrated the benefits of using an intelligent positioning controller versus the more common PLC- or drive-based open-loop control generally designed by OEMs and system integrators. In general, a stress reduction of 10% that can be achieved based on the analysis results can increase a system's lifespan by 50%.

The retrofitted vertical lift fulfilled and exceeded all of Volkswagen's expectations regarding cycle times, stability, reduced wear and power consumption. As calculated during virtual modeling the system's mechanical stress was reduced by more than 15%. At the same time, power consumption decreased and cycle times were reduced by 30%.

Continue reading

At PSI Technics, virtual process modeling goes beyond outlining a desired machine behavior. We offer you an actual representation of the behavior of your specific machines, providing detailed insight into both physical and technical aspects of your installation using real data that far exceeds rough approximations or guesswork.

PSI Technics' virtual process modeling is a comprehensive service offering aimed at optimizing existing factory logistics installations. Our experienced staff uses extensive analysis tools to reveal the optimization potential in your facility. We can assist you with designing and commissioning new installations to help minimize the risk of positioning errors that lead to excessive costs.

After the analysis is complete, we are providing you with a sound basis for improving your installation - giving you a complete picture of tangible optimization benefits that lie ahead.

Our application engineers would be happy to provide recommendations for your specific operating environment. Please call +49 (0) 2630 91590-0 or use the contact form to submit your questions or requests or send an e-mail to support@psi-technics.com.

Many renowned customers rely on solutions from PSI Technics, including:

For more information our application experts are standing by to answer your calls or written requests. Please call +49 (0) 2630 91590-0, use the contact form to submit your queries or send an e-mail to support@psi-technics.com.

Understand. Challenge the status quo. Consistently move forward: This is our vision of progress. We are advancing digitalization and we are leveraging existing data to create added value for our customers.

AUTOMATE. OPTIMIZE. INCREASE QUALITY. SAVE ENERGY.

Immerse yourself in the world of PSI Technics, the competence center for digitalization and automation. We accompany your technical and industrial processes into the future.

You can also use our contact form to make an appointment for an individually guided tour. Click here to visit our digital showroom

From March 21, 2022, you will find us at our new address An der Steinkaul 6a, 56333 Winningen in the industrial and business park "Am Flugplatz". Watch the highlights of the new company building

As image processing experts, we develop custom system solutions for challenging processes, e. g. for the Food Industry - Watch movie for Railway Transport and Logistics - Watch movie for the Automotive Industry - Watch movie for the Raw Materials / Commodities Industry - Watch movie

Designed for the continuous monitoring and visual quality control of production processes.

PSI Technics offers easy-to-use, application-specific digital image processing solutions that are designed for the continuous monitoring and quality control of production processes. Nearly all monitoring and measuring tasks can be automated by means of industrial image processing. Watch movie

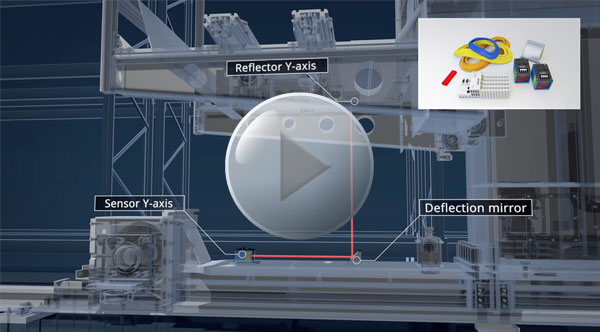

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.Watch movie

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market: For STACKER CRANE applicationsFor BRIDGE CRANE applications

PSI Technics' ARATEC Positioning Solution System is an innovative and advanced solution for industrial positioning applications. Watch movie

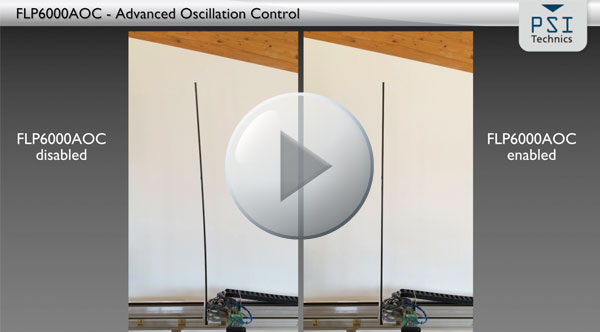

The ARATEC's FLP6000AOC software reduces mast oscillations – even of highly dynamic stacker cranes – to a minimum. The test setup shows that the ARATEC Positioning Solution System with enabled FLP6000AOC compensates for mast oscillations in near-real time, even when the oscillations are caused by external disturbances.

You've got questions, requests or comments about our products and services? Contact our service team and receive a non-binding consultation.

PSI Technics GmbH

An der Steinkaul 6a

56333 Winningen | Germany

PHONE +49 (0) 2630 91590-0

FAX +49 (0) 2630 91590-99

info@psi-technics.com