(PR-inside.com + Free-Press-Release.com, 04/30/2012)

Warehouse logistics present a challenge for many German companies. Outdated positioning systems are still being used in many high-bay warehouses—a situation that is not limited to the automotive industry. At worst, malfunctions or failures lead to warehouse downtimes that can last for several days—a dreadful scenario in terms of "just-in- time" production processes.

Volkswagen AG was faced with this challenge. All stacker cranes in one of their high-bay warehouses in Wolfsburg were still controlled by Trimble's ICS5000 system. The support for this system was discontinued at the end of 2009 and Volkswagen had been looking for a state-of-the-art system that could provide at least an equivalent if not better performance. High reliability, high throughput and long-term availability were vital criteria when it came to choosing a system. Volkswagen opted for the ARATEC Positioning Solution System manufactured by PSI Technics with headquarters near Koblenz, Germany.

Project Description

The ARATEC Positioning Solution System is a stand-alone digital control system that automatically positions stacker cranes in industrial facilities such as high-bay warehouses. The new positioning system was installed at Volkswagen AG's high-bay storage facility in Wolfsburg. Approximately 990 vehicle bodies for Volkswagen Golf, Golf Plus and Tiguan models are stored in an area of 131.2 x 229.6 ft (40 x 70 m). The warehouse serves as an interim storage prior to paint finishing. The system handles approximately 6000 runs per day on each axis and lifts the vehicle bodies to a height of 65.6 ft (20 m).

Since PSI Technics was involved in the modernization analysis and planning early on, the retrofitting was completed very quickly. The process took on average one day per stacker crane. This way, costly downtimes could be kept to a minimum.

So far, PSI Technics retrofitted the traveling and retractable axles of four stacker cranes and is going to modernize a total of ten warehouse stacker cranes.

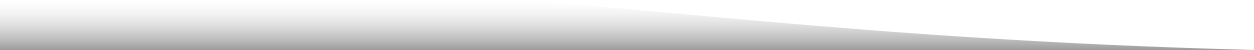

The New Positioning System

The fast and easy integration into Volkswagen AG's existing logistics facilities was a major advantage of the new positioning system. The system permits the continued use of existing components such as PLCs, converters or motor drives. It interfaces with all major process control computers, controllers and inventory management systems. At Volkswagen, the ARATEC Positioning Solution System is controlled by a PLC using the MODBUS TCP protocol. The system provides analog converter control within a range of -10V to +10V. A brake and a safety contact for each axis provide additional system control.

Advantages of Retrofitting:

Easy Integration and Increased Efficiency

Another unique feature that supports a fast commissioning is the system's largely automated confi-guration. ARATEC automatically performs a characterization, eliminating the need for a time-consuming manual control parameter configuration and adjustment. The characterization provides an optimized motion path based on the existing conditions. The system calculates motion profiles, placing particular emphasis on maximum speed and acceleration. During system operation, ARATEC uses feedback from optical distance meters to continuously monitor the stacker crane's movements. It optimizes the motion path in real time and completes storage and retrieval tasks within the shortest possible time. Acceleration and velocity profiles are based solely on linear ramps, irrespective of load, which completely eliminates creeping speed.

The shorter storage and retrieval times ensure the high throughput required by Volkswagen. PSI Technics' web-based software interface provides access to all of the system's characterization, control and diagnostic functionalities. The user-friendly software only requires a brief introduction—no programming skills are needed. Failure detection is another innovative feature of the software. It recognizes minute travel changes or irregularities and triggers early warnings. If problems occur, the software detects them, so they can be addressed proactively at an early stage—an important feature that helps to prevent costly downtimes. The system is also equipped with a 1GB diagnostic memory. Service support is based on system error analyses, which can be performed remotely by PSI Technics' service technicians, if required.

Conclusion:

Reduced downtimes lead to increased productivity

The new positioning solution ARATEC completely fulfilled Volkswagen AG's expectations. The occasional downtimes that occurred with the previous positioning system are no longer an issue. According to Jürgen Bastek, the precision and the performance of the new positioning system were other convincing factors. ARATEC guarantees a reliable warehouse operation with retrofitted stacker cranes for years to come.

Contact:

PSI Technics

Karl-Heinz Förderer

President and CEO

Phone: +49 (0) 2630 91590-0

E-Mail: info@psi-technics.com

ARATEC® TPCC® - Registered in U.S. Patent and Trademark Office

Understand. Challenge the status quo. Consistently move forward: This is our vision of progress. We are advancing digitalization and we are leveraging existing data to create added value for our customers.

AUTOMATE. OPTIMIZE. INCREASE QUALITY. SAVE ENERGY.

Immerse yourself in the world of PSI Technics, the competence center for digitalization and automation. We accompany your technical and industrial processes into the future.

You can also use our contact form to make an appointment for an individually guided tour. Click here to visit our digital showroom

From March 21, 2022, you will find us at our new address An der Steinkaul 6a, 56333 Winningen in the industrial and business park "Am Flugplatz". Watch the highlights of the new company building

As image processing experts, we develop custom system solutions for challenging processes, e. g. for the Food Industry - Watch movie for Railway Transport and Logistics - Watch movie for the Automotive Industry - Watch movie for the Raw Materials / Commodities Industry - Watch movie

Designed for the continuous monitoring and visual quality control of production processes.

PSI Technics offers easy-to-use, application-specific digital image processing solutions that are designed for the continuous monitoring and quality control of production processes. Nearly all monitoring and measuring tasks can be automated by means of industrial image processing. Watch movie

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.Watch movie

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market: For STACKER CRANE applicationsFor BRIDGE CRANE applications

PSI Technics' ARATEC Positioning Solution System is an innovative and advanced solution for industrial positioning applications. Watch movie

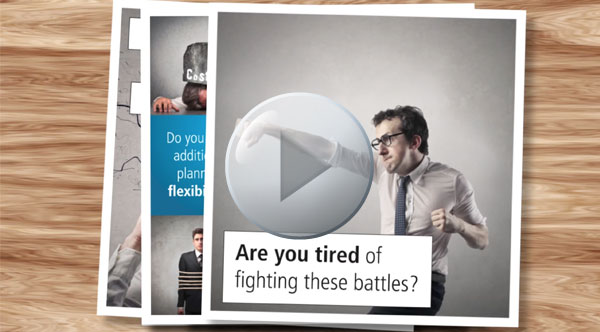

The ARATEC's FLP6000AOC software reduces mast oscillations – even of highly dynamic stacker cranes – to a minimum. The test setup shows that the ARATEC Positioning Solution System with enabled FLP6000AOC compensates for mast oscillations in near-real time, even when the oscillations are caused by external disturbances.

You've got questions, requests or comments about our products and services? Contact our service team and receive a non-binding consultation.

PSI Technics GmbH

An der Steinkaul 6a

56333 Winningen | Germany

PHONE +49 (0) 2630 91590-0

FAX +49 (0) 2630 91590-99

info@psi-technics.com