Hyperspectral imaging:

Hyperspectral cameras extend the range of traditional imaging applications

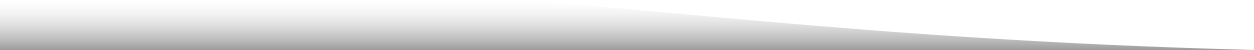

Hyperspectral imaging extends the application range of commonly used grayscale and color cameras.

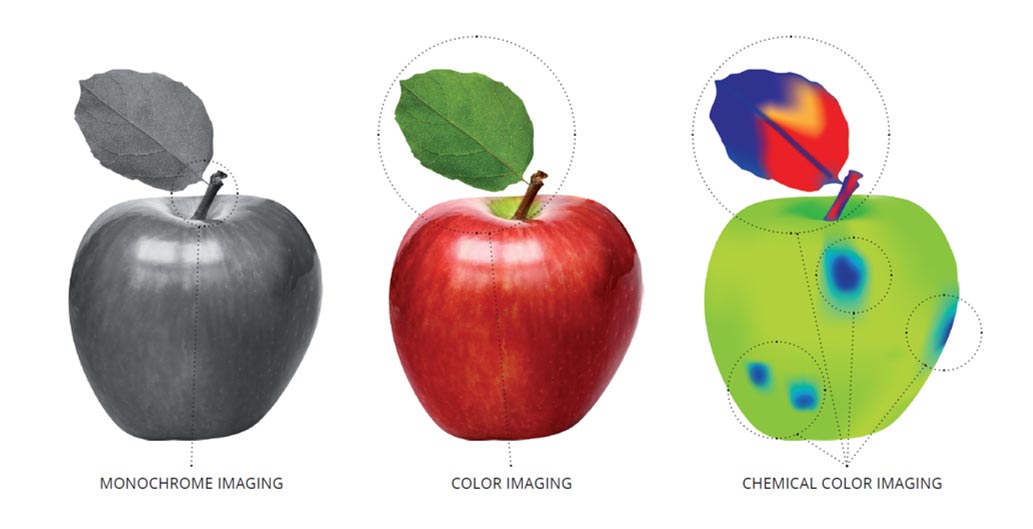

Hyperspectral cameras record over 100 different wavelengths, covering a much broader color spectrum from UV to infrared light. The ability to visualize the infrared spectrum enables the precise identification of specific material signatures or "material fingerprinting". As a result, materials can be clearly identified and classified based on their chemical composition.

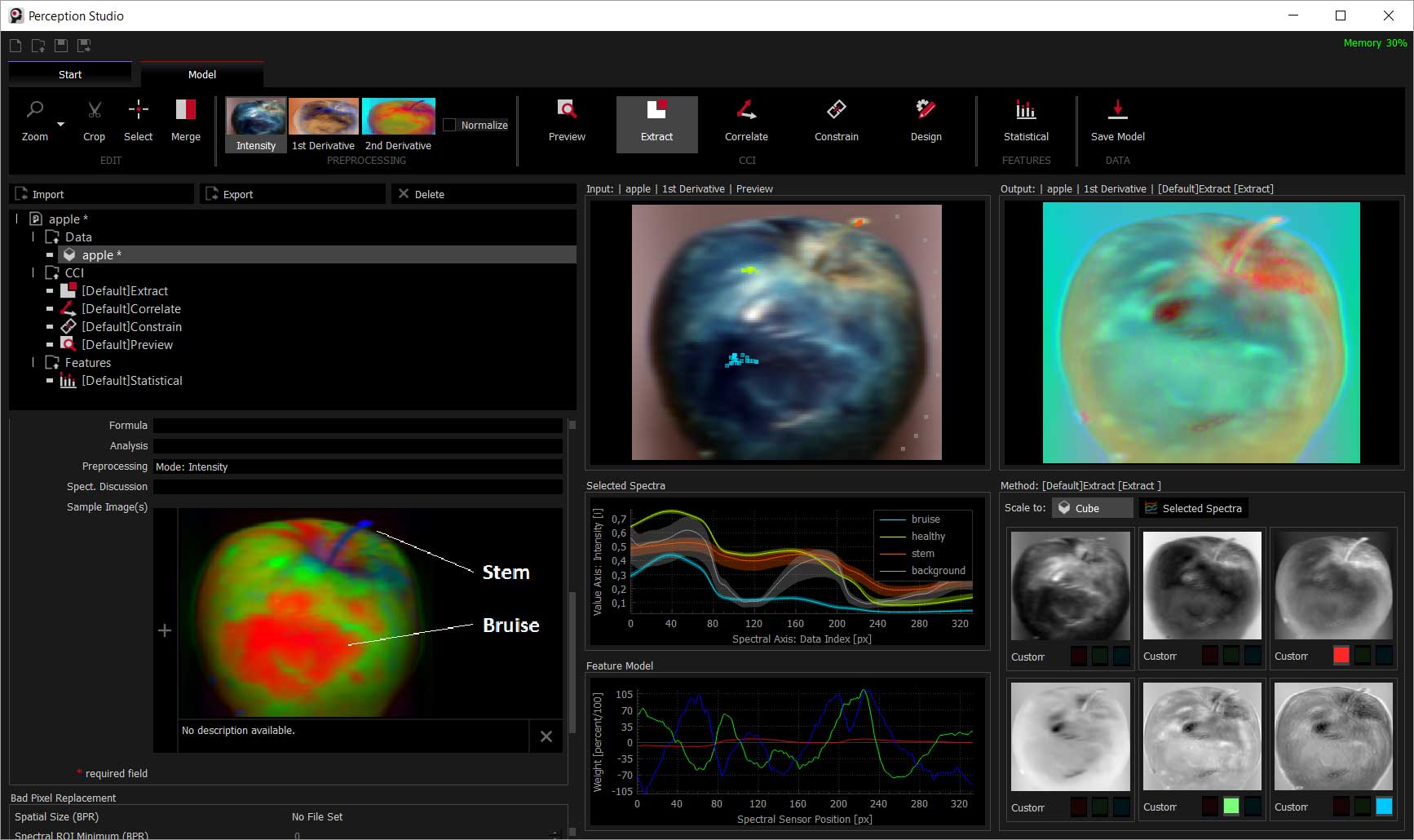

New technologies also assist in complying with new or changing industrial regulations: They significantly speed up analyses, enable repeatable measurements and use durable components that withstand even harsh industrial conditions.

While conventional camera technology is used to optimize and shorten automated production and maintenance processes and increase the quality, productivity and safety of production-related manual and visual inspection and measurement tasks, there are certain industries where grayscale or color cameras are simply unable to achieve the desired results, for example, when it comes to visually differentiating substances with seemingly identical colors or textures.

Wherever conventional image processing systems are unable to provide detailed material analyses, hyperspectral imaging offers an entire range of new possibilities.

The examples listed above are only a few industries that benefit from hyperspectral imaging. PSI Technics specializes in offering individual solutions for complex problems. Contact us today to learn more about our hyperspectral imaging portfolio.

Continue reading

Food industry:

Organic substances, particularly water, lipids or proteins, can be easily distinguished using Chemical Color Imaging (CCI). The composition of meat products, for example, can be measured using hyperspectral imaging without touching or destroying meat samples. The same method can be applied to identify unripe, overripe or spoiled food in the food industry.

Automotive industry:

Hyperspectral imaging helps to precisely identify changes in material structure and enable the unmistakable identification of coating damages or contaminations. Different plastics such as PVC, PETE, PP and PS can reliably be inspected with this method.

Pharmaceutical industry:

Pharmaceutical agents that seem almost identical to the human eye can have distinctly different properties. Hyperspectral analysis enables a clear distinction of those agents based on their chemical composition.

Recycling industry:

The efficiency and productivity of recycling processes can be increased by automatically sorting or filtering out materials using hyperspectral imaging methods.

Woodworking industry:

Humidity can have a significant impact on the quality of wood. Hyperspectral imaging is used to measure the moisture content and to increase product quality.

Raw materials / Commodities industry:

Camera technology has proven especially beneficial for process tasks in demanding work environments. Hyperspectral imaging can also be used in the raw materials or mining industry to differentiate between and identify different minerals and types of rock.

We constantly thrive to develop innovative solutions to expand the application range of industrial image processing and to empower our customers to implement innovative new projects. Hyperspectral imaging enables you to handle a variety of novel testing and measurement tasks that allow you to strategically position your business for the future.

When developing tailor-made solutions, we focus on individual support and a close cooperation with our customers. Our highly professional approach is guaranteed to deliver the best possible results. We leverage the experience obtained from working with renowned companies in various industries to gain deep insight into our customers' industrial processes in order to fulfill the most demanding requirements.

Creative engineering and a wealth of experience with a broad range of hardware and software systems enable us to offer smart solutions that are tailored to your needs. We provide you with expert advice, custom design and service, as well as all required hardware and software components – from a single source.

Our application engineers and technicians advise and assist you and use their extensive expertise to leverage the development process for optimizing processes and solutions.

You, too, can benefit from becoming a PSI Technics partner – we continuously work to provide you with the safest, most efficient and optimized solutions for your business.

Image source: *Perception Park GmbH **Stemmer Imaging GmbH

PSI Technics, Inodo, AdobeStock, Fotolia

Understand. Challenge the status quo. Consistently move forward: This is our vision of progress. We are advancing digitalization and we are leveraging existing data to create added value for our customers.

AUTOMATE. OPTIMIZE. INCREASE QUALITY. SAVE ENERGY.

Immerse yourself in the world of PSI Technics, the competence center for digitalization and automation. We accompany your technical and industrial processes into the future.

You can also use our contact form to make an appointment for an individually guided tour. Click here to visit our digital showroom

From March 21, 2022, you will find us at our new address An der Steinkaul 6a, 56333 Winningen in the industrial and business park "Am Flugplatz". Watch the highlights of the new company building

As image processing experts, we develop custom system solutions for challenging processes, e. g. for the Food Industry - Watch movie for Railway Transport and Logistics - Watch movie for the Automotive Industry - Watch movie for the Raw Materials / Commodities Industry - Watch movie

Designed for the continuous monitoring and visual quality control of production processes.

PSI Technics offers easy-to-use, application-specific digital image processing solutions that are designed for the continuous monitoring and quality control of production processes. Nearly all monitoring and measuring tasks can be automated by means of industrial image processing. Watch movie

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.Watch movie

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market: For STACKER CRANE applicationsFor BRIDGE CRANE applications

PSI Technics' ARATEC Positioning Solution System is an innovative and advanced solution for industrial positioning applications. Watch movie

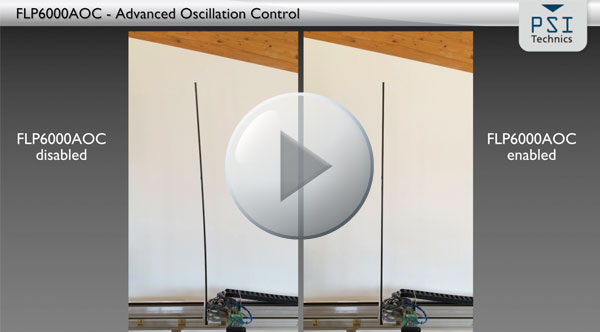

The ARATEC's FLP6000AOC software reduces mast oscillations – even of highly dynamic stacker cranes – to a minimum. The test setup shows that the ARATEC Positioning Solution System with enabled FLP6000AOC compensates for mast oscillations in near-real time, even when the oscillations are caused by external disturbances.

You've got questions, requests or comments about our products and services? Contact our service team and receive a non-binding consultation.

PSI Technics GmbH

An der Steinkaul 6a

56333 Winningen | Germany

PHONE +49 (0) 2630 91590-0

FAX +49 (0) 2630 91590-99

info@psi-technics.com