The food industry is one of the sectors where quality control and food safety are of paramount importance. Products must reach customers intact and in perfect condition and important data, such as the BBD (best-before date), must be correctly printed on the packaging. Defective or damaged packaging must be detected and avoided to ensure that the quality and the shelf-life of foods remains uncompromised and products are free from foreign objects.

Often, quality control in the food industry is preformed manually and products are sampled and sorted out by hand. These monotonous activities impair concentration. Production flaws or leaks may go undetected and items that should have been rejected might end up on grocery store shelves. Moreover, this method does not account for defects that are invisible to the human eye – for example, air that is trapped in the seams of sealed food packaging.

Using industrial image processing to automate the quality control of foods and food packaging is one way to make quality inspection in this industry safer and more efficient.

2D or 3D cameras and dedicated image processing software automatically inspect and analyze products during production.

Image processing systems detect and process a wide variety of parameters, such as:

Image processing systems monitor 100% of all processed products and automatically remove damaged foods or packaging from production. The speed and accuracy of these systems expedite production and improve both safety and quality control.

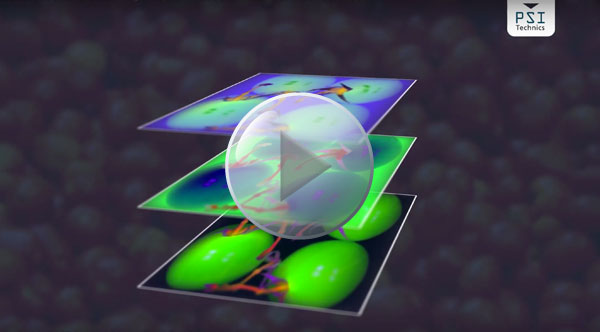

Hyperspectral imaging significantly extends the performance of automated quality control systems by adding a hyperspectral data to the surface view of an inspected object:

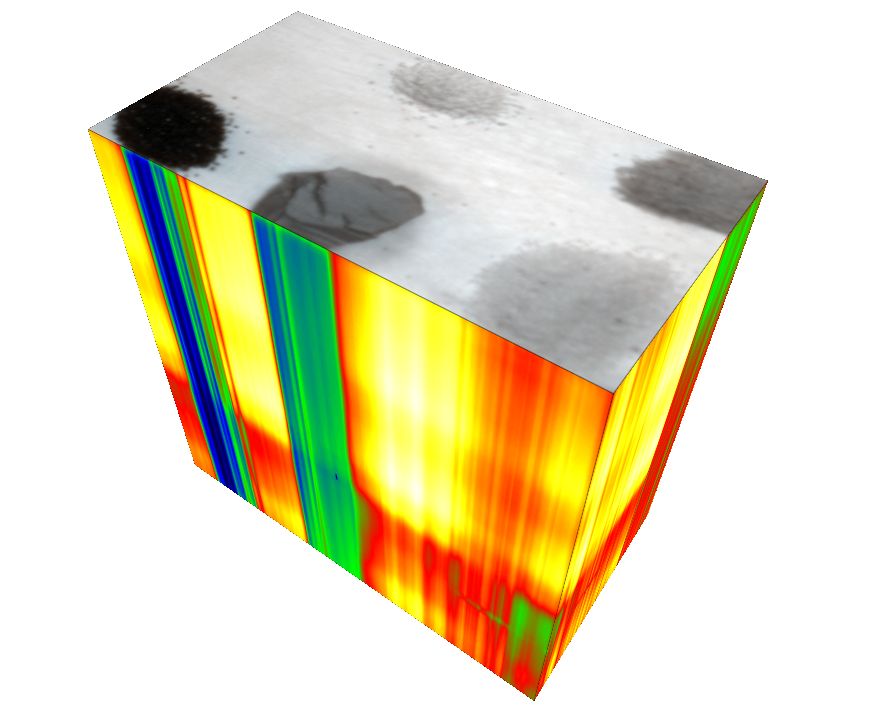

Hyperspectral imaging makes hidden food properties visible. It reveals, for example, information about the fat and water content of a piece of meat. Plastics, for example, can be clearly differentiated from organic materials, to precisely detect foreign objects during production.

Even the quality control of bulk foods like salt or sugar can be substantially enhanced using hyperspectral imaging. Hyperspectral imaging uses the absorption signature of the monitored wavelength range (visible light, UV or infrared range) to detect the smallest impurities, even when their color is nearly indistinguishable from the color of the actual product.

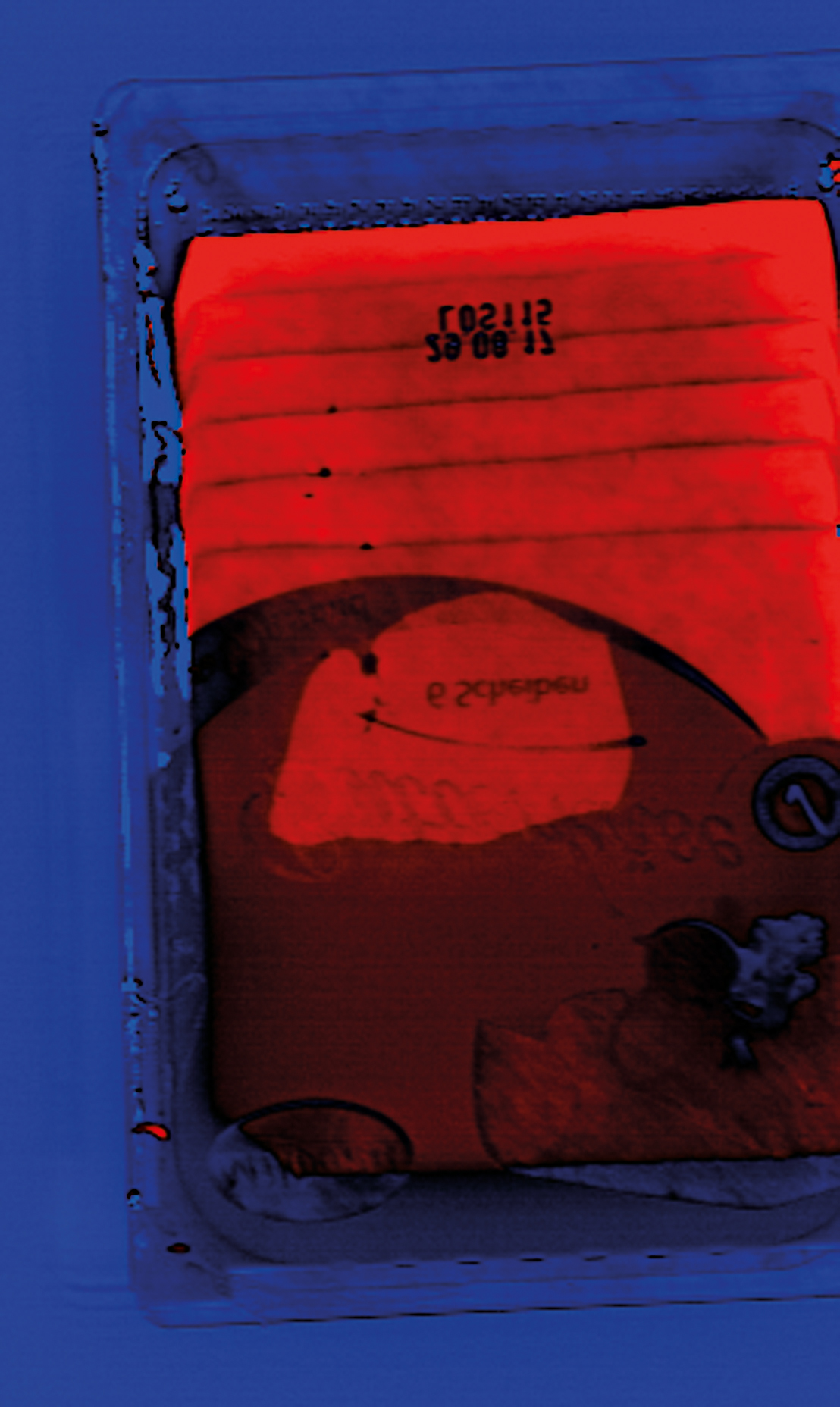

Airtight packaging ensures that food does not perish until it ultimately reaches the customer. Any packaging flaws can cause foods to spoil quickly. Until now trapped air or food inclusions in sealed seams went undetected in products that are packaged in printed film or foil.

Hyperspectral imaging sees through sealed seams of film or foil packaging to ensure that damaged or contaminated products are detected and removed during packaging or production. Hyperspectral imaging guarantees that every product is fully inspected and passes quality control.

Camera systems can be directly integrated into the production workflow to ensure seamless processes at early on in the value chain. Visual and manual controls can be replaced by image processing systems to guarantee a comprehensive automated quality control.

The systems are virtually maintenance-free, have a low susceptibility to interference and are available 24 hours a day, 7 days a week. When high quality products are the key to success in your company, cutting-edge image processing technology significantly contributes to your success.

Combined with special enclosures and system components industrial imaging systems can also be used in hygienically demanding environments that are often found in the food industry. Adequate technology is used to protect imaging systems from spray water and extreme temperatures to ensure reliable quality control in areas that are generally off-limits to employees. The same applies to process monitoring applications, for example, in the field of proactive maintenance where the maintenance staff needs to receive automated alerts or error messages when process parameters change.

In summary, industrial image processing systems – and hyperspectral imaging in particular – are used to inspect product attributes and characteristics

• automatically,

• non-destructively

• and comprehensively.

The correct use of these innovative products guarantees added value when compared to conventional visual and manual inspections.

In addition to quality control, industrial image processing systems enable the automated recording of both product and process data. The data are mainly used for comprehensive quality control in real time and for monitoring production processes to ideally avoid any interferences or malfunctions.

In addition, the recorded data can be used to unlock hidden economic potential.

Combining recorded data with additional parameters enables targeted analyses for:

Image Source: PSI Technics, Inodo, Optikon, AdobeStock, Fotolia, Perception Park, Kai Myller

Understand. Challenge the status quo. Consistently move forward: This is our vision of progress. We are advancing digitalization and we are leveraging existing data to create added value for our customers.

AUTOMATE. OPTIMIZE. INCREASE QUALITY. SAVE ENERGY.

Immerse yourself in the world of PSI Technics, the competence center for digitalization and automation. We accompany your technical and industrial processes into the future.

You can also use our contact form to make an appointment for an individually guided tour. Click here to visit our digital showroom

From March 21, 2022, you will find us at our new address An der Steinkaul 6a, 56333 Winningen in the industrial and business park "Am Flugplatz". Watch the highlights of the new company building

As image processing experts, we develop custom system solutions for challenging processes, e. g. for the Food Industry - Watch movie for Railway Transport and Logistics - Watch movie for the Automotive Industry - Watch movie for the Raw Materials / Commodities Industry - Watch movie

Designed for the continuous monitoring and visual quality control of production processes.

PSI Technics offers easy-to-use, application-specific digital image processing solutions that are designed for the continuous monitoring and quality control of production processes. Nearly all monitoring and measuring tasks can be automated by means of industrial image processing. Watch movie

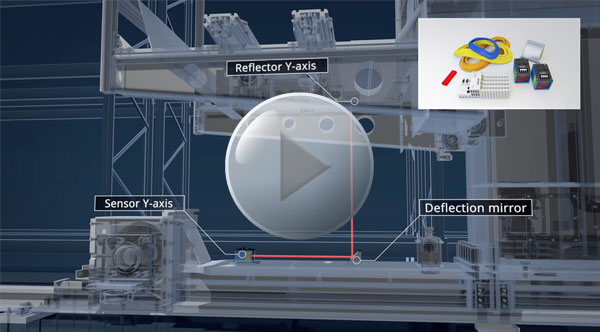

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.Watch movie

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market: For STACKER CRANE applicationsFor BRIDGE CRANE applications

PSI Technics' ARATEC Positioning Solution System is an innovative and advanced solution for industrial positioning applications. Watch movie

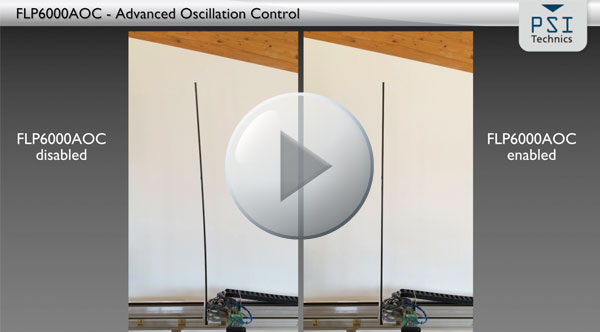

The ARATEC's FLP6000AOC software reduces mast oscillations – even of highly dynamic stacker cranes – to a minimum. The test setup shows that the ARATEC Positioning Solution System with enabled FLP6000AOC compensates for mast oscillations in near-real time, even when the oscillations are caused by external disturbances.

You've got questions, requests or comments about our products and services? Contact our service team and receive a non-binding consultation.

PSI Technics GmbH

An der Steinkaul 6a

56333 Winningen | Germany

PHONE +49 (0) 2630 91590-0

FAX +49 (0) 2630 91590-99

info@psi-technics.com