(PSI Technics, 07/03/2012)

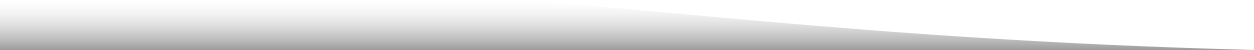

A new trolley wheel inspection system based on industrial image processing prevents costly production downtimes.

Project Description

Power & Free systems consist of two tracks: An overhead ("Power") track that holds a conveyor or carrier chain and a lower "Free" track. The overhead track transports the chain-driven trolleys.

Initial Situation

At Volkswagen AG in Wolfsburg the final assembly work is done while the vehicle bodies are hanging from the Power & Free conveyor system before the cars roll off to the next production stage.

The high throughput considerably affects the assembly line components.

Wear and abrasion leads to:

The Challange

"A product that was quick to install and would provide a reliable trolley wheel inspection was important to us. We wanted to proactively detect material fatigue to avoid corrective measures", says Jürgen Bastek, Manager of Maintenance at Volkswagen AG.

The Solution

Fully automated industrial image processing with 2D and 3D cameras:

Project Duration

Volkswagen has been successfully using the Inline Control System since June 2011.

It was installed within a couple of hours during planned production-free maintenance periods.

Contact:

PSI Technics

Karl-Heinz Förderer

President and CEO

Phone: +49 (0) 2630 91590-0

E-Mail: info@psi-technics.com

ARATEC® TPCC® - Registered in U.S. Patent and Trademark Office

Links>Application Reports >Industrial Image Processing |

Downloads>Application Report - Volkswagen AG: Reliable Systems Guarantee Operational and Process Stability (PDF) |

Understand. Challenge the status quo. Consistently move forward: This is our vision of progress. We are advancing digitalization and we are leveraging existing data to create added value for our customers.

AUTOMATE. OPTIMIZE. INCREASE QUALITY. SAVE ENERGY.

Immerse yourself in the world of PSI Technics, the competence center for digitalization and automation. We accompany your technical and industrial processes into the future.

You can also use our contact form to make an appointment for an individually guided tour. Click here to visit our digital showroom

From March 21, 2022, you will find us at our new address An der Steinkaul 6a, 56333 Winningen in the industrial and business park "Am Flugplatz". Watch the highlights of the new company building

As image processing experts, we develop custom system solutions for challenging processes, e. g. for the Food Industry - Watch movie for Railway Transport and Logistics - Watch movie for the Automotive Industry - Watch movie for the Raw Materials / Commodities Industry - Watch movie

Designed for the continuous monitoring and visual quality control of production processes.

PSI Technics offers easy-to-use, application-specific digital image processing solutions that are designed for the continuous monitoring and quality control of production processes. Nearly all monitoring and measuring tasks can be automated by means of industrial image processing. Watch movie

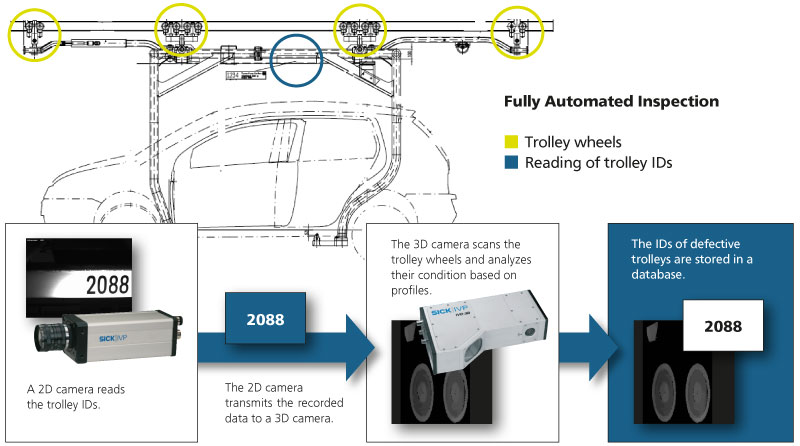

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.Watch movie

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market: For STACKER CRANE applicationsFor BRIDGE CRANE applications

PSI Technics' ARATEC Positioning Solution System is an innovative and advanced solution for industrial positioning applications. Watch movie

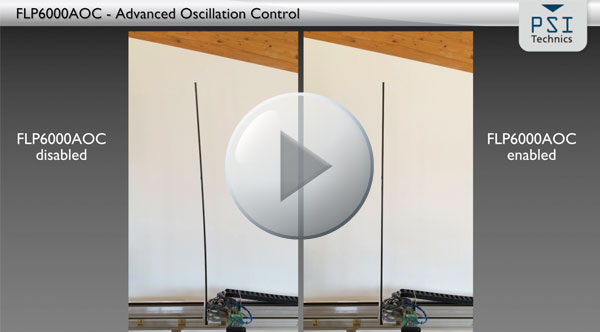

The ARATEC's FLP6000AOC software reduces mast oscillations – even of highly dynamic stacker cranes – to a minimum. The test setup shows that the ARATEC Positioning Solution System with enabled FLP6000AOC compensates for mast oscillations in near-real time, even when the oscillations are caused by external disturbances.

You've got questions, requests or comments about our products and services? Contact our service team and receive a non-binding consultation.

PSI Technics GmbH

An der Steinkaul 6a

56333 Winningen | Germany

PHONE +49 (0) 2630 91590-0

FAX +49 (0) 2630 91590-99

info@psi-technics.com