| |

We provide you with the safest, most efficient and optimized solutions for warehouse logistics.

In logistics, industrial machines are critical for the production throughput of goods and merchandise. Over time, installations and machines become prone to failures.

When deciding to modernize existing installations, you need to consider economic advantages and potential risks - for example, the relation between investment costs and expenses that may incur due to potential defects or downtimes.

PSI Technics has many years of experience with a wide range of applications. Experience has taught us that a well-planned optimization reduces those risks to a minimum and enables long-term planning.

When you entrust us with consulting, planning, the implementation and support of your project, we optimize the cycle times and the energy efficiency of your stacker cranes or bridge crane installation and other rail-guided industrial vehicles - you benefit from increased throughput and cost-efficient energy management, regardless of the make or model of your installation.

OPTIMIZATION - MODERNIZATION - RETROFITTING

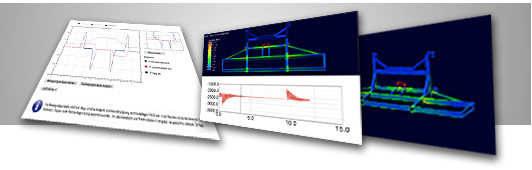

Identifying Optimization Potential through Performance Analysis and Virtual Modeling

PSI Technics uses performance analysis to improve the performance and the energy consumption of your installation, providing you with a complete picture of the tangible optimization potential of your facility. In addition, we evaluate the condition of existing components that could exhibit weak spots in the near future, so you can plan ahead to avoid costly disruptions.

Using virtual modeling we offer you a "glimpse into the future" of your installation, enabling you to predict and thus avoid costly downtimes for new and existing installations, in addition to reducing costs in the long run.

After the analysis is complete, we provide you with a sound basis for improving your installation - giving you a complete picture of the tangible optimization benefits that lie ahead.

International companies that chose PSI Technics as their partner are already reaping the long-term planning benefits that our services provide. Many world-class customers are taking advantage of our solutions, including one of the biggest manufacturers of rolled carbon and stainless steel in Rockport, Indiana, the world's biggest airport logistics terminal in East Asia and a renowned German car manufacturer.

We are committed to improving the safety of your installation.

Learn more about how you can minimize your warehousing costs and select a modernization option that is right for you.

Click here to read additional application reports

APPLICATION REPORT

Mercedes Benz Factory, Düsseldorf, Germany - Increased Throughput at a Vehicle Body Warehouse: Positioning System Modernization

The first stacker crane in the vehicle body warehouse was retrofitted and commissioned with PSI Technics’ ARATEC Positioning Solution System within a single day.

The client uses the FLP6000EOS Energy Optimizing Software to achieve an optimum travel profile that reduces wear and optimizes energy consumption.

The drives and controllers of the existing system were retained, since the ARATEC system interface is 100% compatible with the previously used ICS5000L interface.

ARATEC substantially improved warehouse throughput by 15%, while the system’s optimized travel profile simultaneously reduces machine wear and tear.

Click here to read the complete application report

Click here to read additional application reports

Learn more about how you can minimize your warehousing costs and select a modernization option that is right for you.

APPLICATION REPORT

Upgrade Option for ICS5000L Customers - The ARATEC Positioning Solution System at Work in a High-Bay Warehouse of an International Cargo Terminal

Hong Kong International Airport is the biggest air freight hub in the world. To guarantee the fail-safe operation of their logistics systems in their terminal warehouses, airport operator Hong Kong Air Cargo Terminals Limited (Hactl) relied on positioning systems provided by PSI Technics and started modernizing their stacker cranes in 2010.

[...] "The references of PSI Technics' positioning solution and the excellent service quality were crucial for our investment decision", concludes Wong, Technical Coordinator at Hactl.

Click here to read the complete application report

Click here to read additional application reports

Learn more about how you can minimize your warehousing costs and select a modernization option that is right for you.

INDUSTRIAL POSITIONING SYSTEMS

A North-American Steel Manufacturer Relies on PSI Technics' ARATEC Positioning Solution System

One of the biggest manufacturers of cold-rolled carbon and steel in Rockport, Indiana, decided to retrofit their outdated ICS5000L bridge crane positioning system with PSI Technics' ARATEC Positioning Solution System.

The ARATEC Positioning Solution System is an efficient, reliable system that easily integrates into the existing warehouse infrastructure.

"We greatly appreciate the cooperation, professionalism, service and quality product(s) that PSI Technics has offered us. Your solution works. It works because of your company and team members commitment to success", says a Senior Electrical Engineer of the company.

Click here to read additional application reports

Learn more about how you can minimize your warehousing costs and select a modernization option that is right for you.

Would you like to receive information on additional services or products?

We would be happy to prepare a detailed estimate with the relevant technical specifications for your application. To learn more about our solutions, including crane and transport vehicle positioning and sensor protection, please contact us by phone or e-mail.

Phone: +49 (0) 2630 91590-0

info@psi-technics.com

www.psi-technics.com

Storage & Retrieval Simplified. Increase Quality. Save Energy.

Do you have comments or suggestions regarding our PSI Technics Newsletter?

Would you like to receive information on additional services or products?

We greatly appreciate your feedback.

Learn more at www.psi-technics.com

Legal Information/Privacy Statement :: Contact :: Unsubscribe :: Recommend

Commercial Registry Entry: HRB 20019 Amtsgericht Koblenz

Managing Director: Karl-Heinz Förderer

Tax ID: 22/653/043/13 Germany | VAT ID: DE243676582

ARATEC® TPCC® - Registered in U.S. Patent and Trademark Office

Awards

|

|