You have been working to streamline your intralogistics facility for years or even decades. Today, your value chain is as complex as it is sophisticated. More importantly, it is absolutely imperative for the success of your company to remain flexible in today's hyper-competitive environment. To be able to take full advantage of the complete potential your facility has to offer, evaluating intralogistics processes and components from a single point of view is not enough. Industry 4.0 is but one of the trends successful companies are considering that has opened up revolutionary possibilities for productivity increases.

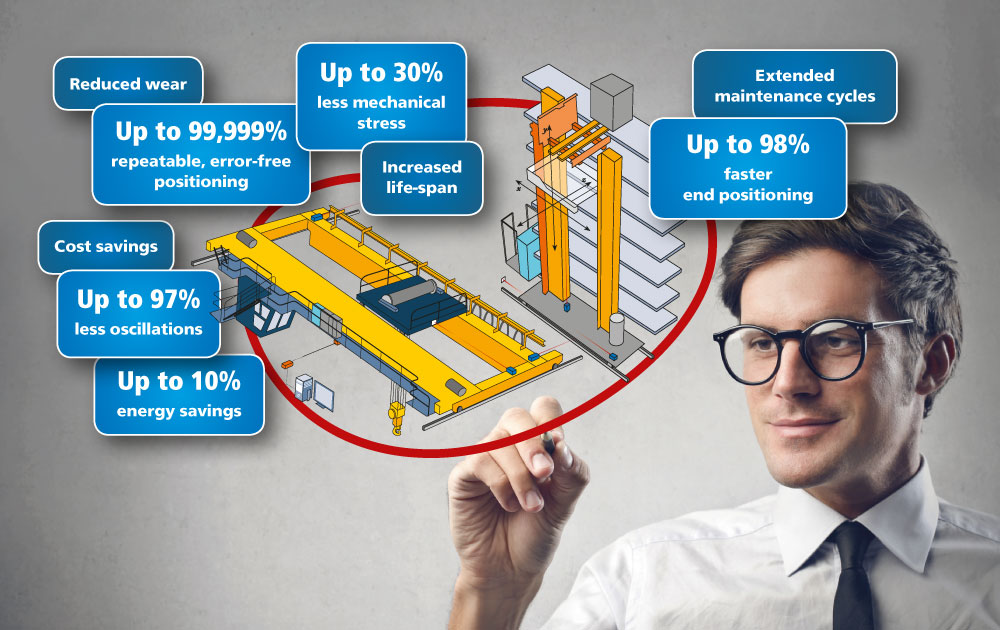

To reveal optimization potential in automated warehouses PSI Technics considers three essential factors:

This unique software delivers precise motion path data for the rail-guided vehicles in your facility and enables us to plan specific measures for effectively reducing wear and energy consumption and for increasing the throughput of your warehouse. The analysis data are presented in an easy to understand format. They include recommendations which provide you with a comprehensive overview of the kinematic potential in your warehouse.

We take an in-depth look at the logistics processes in your warehouse and identify optimization potentials in your value chain. Our approach includes analyzing and evaluating your warehouse management system (WMS), the material flow of individual goods as well as picking zones, motion-related processes and handling times for incoming or outgoing goods to identify and eliminate bottlenecks.

We calculate potential cost savings and turnover increases for you that are based on our analysis data for enhanced ASRS throughput. We also calculate the investment risk that is associated with potential improvements and the corresponding ROI. By leveraging our experience with mechatronic systems in intralogistics facilities we are able to translate motion- and process-related data into Key Performance Indicators (KPI) and provide recommendations to improve productivity of your existing equipment.

After performing an extensive analysis of your facility, we become familiar with your processes and identify potential weak spots. This enables us to strategically plan the correct modernization or optimization measures without disrupting your material flow. Our automation and industrial image processing experts have extensive experience when it comes to planning, coordinating and implementing complex projects and will provide modernization solutions that are tailored to your needs.

Are you looking to gain better insight into your intralogistics facilities that will lead to the identification of hidden potentials or weak spots? We examine your warehouse from a variety of perspectives to provide you with an in-depth analysis of the actual condition of your facility. Apart from a Motion Analysis of your rail-guided vehicles we examine your intralogistics processes and perform a profitability analysis.

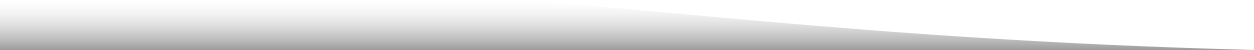

Based on the analysis of the current warehouse condition, we reveal modernization and optimization potentials for rail-guided machines, material and information flow, warehouse logistics, warehouse management as well as energy management, aiming to reduce costs, increase throughput and ultimately enhance the productivity and longevity of the critical supply chain assets in your facility.

We provide you with specific recommendations and proposals that will help you to fully exploit the optimization potentials that we identified in step 2. Our long-standing expertise in the automation and intralogistics industry ensures an efficient and reliable modernization process. Click here for an overview of our comprehensive modernization and retrofitting portfolio.

Should you decide to take advantage of our recommendations and proposed solutions, we offer to take care of the optimization or modernization for you. Many renowned international clients rely on our services which highlights our extensive and proven expertise in the industry. All modernization and optimization steps are clearly laid out in a custom proposal based on the preceding analyses.

If desired, we assist you even after the successful modernization of your intralogistics facility. Automated warehouses need to be periodically re-evaluated within the context of a Continuous Improvement Process (CIP) that enables you to strengthen your position and gain a competitive advantage by reaping the benefits from the latest developments of Industry 4.0. We support this process by providing continuous assessments for rail-guided vehicles and logistic workflows to identify and reduce cost drivers, bottlenecks and risk factors early on.

For an even more efficient warehouse monitoring solution, we offer a condition-based performance monitoring tool that consists of proven software and sensors that are tailored to your needs. It allows you to continuously monitor the vehicles in your intralogistics facility and to identify any maintenance or modernization requirements in a timely manner.

This ensures that your facility operates at peak performance at all times, easily adapts to new requirements, minimizes the risk of downtimes and unexpected costs for repairs or accumulated modernization requirements.

Today's competitive environment is only going to get more challenging in the future. Businesses that seek to understand the strengths and opportunities of their intralogistics systems will position themselves for long-term, mutual success in a rapidly changing world. Call us today!

For more information our application experts are standing by to answer your calls or written requests. Please call +49 (0) 2630 91590-0, use the contact form to submit your queries or send an e-mail to support@psi-technics.com.

Understand. Challenge the status quo. Consistently move forward: This is our vision of progress. We are advancing digitalization and we are leveraging existing data to create added value for our customers.

AUTOMATE. OPTIMIZE. INCREASE QUALITY. SAVE ENERGY.

Immerse yourself in the world of PSI Technics, the competence center for digitalization and automation. We accompany your technical and industrial processes into the future.

You can also use our contact form to make an appointment for an individually guided tour. Click here to visit our digital showroom

From March 21, 2022, you will find us at our new address An der Steinkaul 6a, 56333 Winningen in the industrial and business park "Am Flugplatz". Watch the highlights of the new company building

As image processing experts, we develop custom system solutions for challenging processes, e. g. for the Food Industry - Watch movie for Railway Transport and Logistics - Watch movie for the Automotive Industry - Watch movie for the Raw Materials / Commodities Industry - Watch movie

Designed for the continuous monitoring and visual quality control of production processes.

PSI Technics offers easy-to-use, application-specific digital image processing solutions that are designed for the continuous monitoring and quality control of production processes. Nearly all monitoring and measuring tasks can be automated by means of industrial image processing. Watch movie

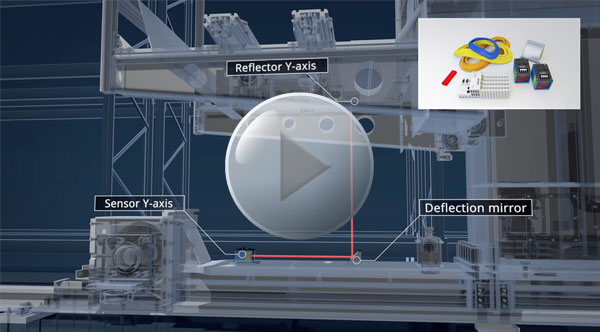

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.Watch movie

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market: For STACKER CRANE applicationsFor BRIDGE CRANE applications

PSI Technics' ARATEC Positioning Solution System is an innovative and advanced solution for industrial positioning applications. Watch movie

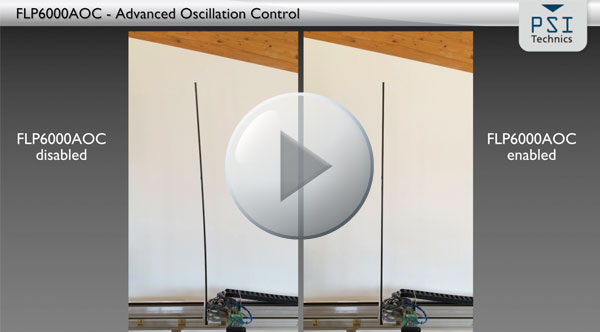

The ARATEC's FLP6000AOC software reduces mast oscillations – even of highly dynamic stacker cranes – to a minimum. The test setup shows that the ARATEC Positioning Solution System with enabled FLP6000AOC compensates for mast oscillations in near-real time, even when the oscillations are caused by external disturbances.

You've got questions, requests or comments about our products and services? Contact our service team and receive a non-binding consultation.

PSI Technics GmbH

An der Steinkaul 6a

56333 Winningen | Germany

PHONE +49 (0) 2630 91590-0

FAX +49 (0) 2630 91590-99

info@psi-technics.com