With mupudia PSI Technics offers you a digital assistant system that guides your workforce through your workflows.

The smart digital assistance system helps you support your workforce – even staff members with little or no experience. Digital assistance systems allow you to digitalize the existing knowledge in your company in a sustainable way.

EMPOWER your people.

PRESERVE your knowledge.

DIGITALIZE your process.

AMPLIFY your possibilities.

Learn more at www.mupudia.com about the great benefits of the digital assistant.

With mupudia PSI Technics offers you a digital assistant system that guides your workforce through your workflows.

mupudia is a multi-purpose digital assistant that is well-suited for a wide range of industrial processes, like:

Learn more at www.mupudia.com about the great benefits of the digital assistant.

1. Reduced Employee Workload

mupudia guides your employees through your processes and allows them to focus on every single step. Your processes become more resilient and less prone to human errors.

2. Faster training of new hires

mupudia enables you to train new employees faster and more efficiently in significantly less time. This frees up experienced staff members who can focus on creating added value in the process chain.

3. Integration of skilled professionals

The app automatically translates content into more than 70 languages. This eliminates language barriers and promotes an efficient collaboration in multilingual teams.

Industrial Image Processing for the Automotive Industry

An automobile consists of nearly 12,000 individual parts and every single one needs to work flawlessly – because the safety of your customers and your brand image demand perfection.

Superior quality can be achieved with our camera systems that are optimally tuned to production environments and are used in a wide variety of processes in the automotive and automotive supply industries.

Image processing systems from PSI Technics optimize production processes throughout the value chain. Our solutions detect defects, provide traceability and prevent production downtimes. They improve products and processes in single step and help avoid costly returns and recalls.

Continue readingPSI Technics uses sophisticated systems and processes to provide customized solutions, for example: We help you find the perfect camera system for your application. Volkswagen uses PSI Technics' image processing system (Inline Control System) with 2D or 3D cameras to monitor the trolley wheels of a Power & Free vehicle assembly line.

The system is used for quality and molding inspections during production. 2D and 3D cameras inspect pressed parts, drawn parts and semi-finished products for the smallest cracks, scratches or coating thickness. The inspection can take place at the supplier end or during production. Camera systems are also used to automatically check for the physical presence of components, such as screws, oil filter caps, etc.

Hyperspectral imaging helps to precisely identify changes in material structure and enable the unmistakable identification of uneven paint layers, coating damages or contaminations. Leather applications or different plastics, such as PVC, PETE, PP and PS, can reliably be inspected with this method. Even seal-tight tests for fats or oils don't represent any challenges.

The quality of coated surfaces can be examined for the smallest scratches and dull spots using deflectometry or photometric stereo.

Industrial Image Processing for Railway Transport and Logistics

Every single component in high-speed trains is subject to extreme mechanical stress. The early identification of weak spots is crucial when it comes to the safety and mobility of people.

The system we developed for Deutsche Bahn AG automatically inspects high-speed trains from all angles. Our imaging systems safely detect even the smallest irregularities and flag them as hot spots – so that issues can be resolved before outages and consequential damages occur.

The inspection results are stored and archived on our servers to ensure that quality-related issues can be traced and addressed.

Continue readingPSI Technics image processing systems enable the recording and structuring of vast amounts of data that in turn translates into technological, safety-related or economic benefit for customers. For instance, data mining can be used to identify creeping wear at an early stage to schedule preventive maintenance, to prevent downtimes and to increase machine availability.

Our engineers developed a camera-based automated train inspection system to enable an automated, condition-based maintenance for trains. The system records damages of any train that passes the system, for example, when it enters a depot or drives through a dedicated "inspection tunnel". The recorded data is sent directly to the Inspect software.

Deep Learning algorithms enable a fast and efficient classification of recorded pictures. Using taught-in templates of acceptable/unacceptable parts, a deep learning system automatically recognizes any deviations to ensure that damaged manufacturing parts can be automatically identified and removed from production.

Artificial intelligence (AI) algorithms enable camera systems to learn from samples. Based on large volumes of recorded and analyzed data modern machine learning algorithms help to continuously improve the evaluation of quality-related properties. The obtained data can subsequently be used for further processing and analysis.

Industrial Image Processing for the Food Industry

We rely on food quality and safety on a daily basis. That's why quality control is of utmost importance in this industry.

Our imaging systems ensure that your products are safe. They detect plastic particles in fresh produce like cold meats and cheese and small bits of glass in yogurt. They monitor the quantity and composition of food and check that the packaging is airtight.

Our systems guarantee repeatability and the traceability of errors, providing transparency and a solid foundation for your business decisions.

Continue readingWherever conventional image processing systems are unable to provide detailed material analyses, hyperspectral imaging offers an entire range of new possibilities.

Organic substances, particularly water, lipids or proteins, can be easily distinguished using Chemical Color Imaging (CCI). The composition of meat products, for example, can be measured using hyperspectral imaging without touching or destroying meat samples. The same method can be applied to identify unripe, overripe or spoiled food in the food industry.

Foreign substances like plastic, shards of glass, metal or machine oil are easily identified at an early stage to prevent costly product recalls and loss of product reputation. Hyperspectral imaging can be used to examine a wide variety of food packagings, for instance, cheese or cold cut packagings, for air tightness or quality issues, since the smallest packaging leaks or tears can contaminate or spoil the contents.

Hyperspectral imaging is also used to identify the quality, purity, composition and contents of various foods and formulations: Ready-made foods, pizza, cereal, instant meals, seasoning mixes, baked goods, cheese, milk products, sausages and cold cuts/meats, fruits and vegetables, etc.

Industrial Image Processing for the Raw Materials / Commodities Industry

The composition of raw materials is vital for the quality of products and the volume of production rejects. In short: It directly influences your manufacturing profitability.

Hyperspectral imaging sees below the surface of any material. It detects everything from moisture content in wood to impurities in clay: Flawed materials can be removed from production, recycled or claimed.

You can rest assured that we develop tailor-made technical solutions that provide reliable results in the long run – even in harsh industrial environments.

Continue readingCamera technology has proven especially beneficial for process tasks in demanding work environments. Hyperspectral imaging can also be used in the mining industry and in the production of raw materials to differentiate between and identify the quality of various minerals, ores and types of rock.

Those industries often rely on outdated technologies, such as x-ray technology. Hyperspectral cameras record over 100 different wavelengths, covering a much broader color spectrum when it comes to evaluating the purity of a wide variety of substances. Clays used in the ceramics industry can, for example, be checked on a conveyor belt or sorter for their humidity content prior to firing to help prevent breakage and save energy and costs.

Humidity can have a significant impact on the quality of wood. Hyperspectral imaging is used to measure the moisture content and to increase product quality.

Considerably Reduces Costs by Using Cutting-edge Camera Solutions

As an experienced systems integrator, PSI Technics retrofits and replaces manual measuring and inspection systems with cutting-edge image processing technology. Powerful 2D and 3D cameras, for example, identify defective products during the early manufacturing stages - considerably cutting costs and increasing the safety of automated production processes as compared to manual inspections.

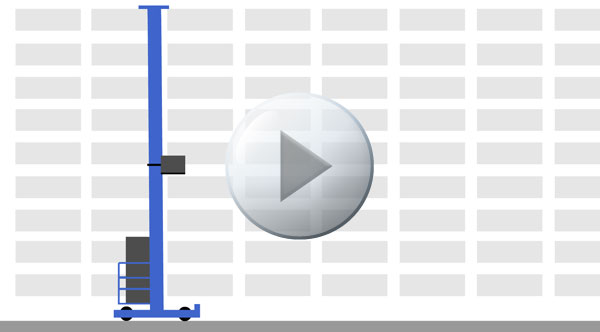

ARATEC Positioning Solution System – Powerful Modernization for Stacker Cranes

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications. In fully automated high-bay warehouses, for example, ARATEC instructs stacker cranes to move to the storage position's target coordinates to ensure that all storage and retrieval operations are carried out with high accuracy in the shortest amount of time. In addition, wear and tear can be reduced to a minimum due to an almost 100% compensation of mast oscillations.

Advantages of the ARATEC:

ARATEC - Challenges Inspire Performance.

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.

We are going to show you what your logistics system can do.

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market.

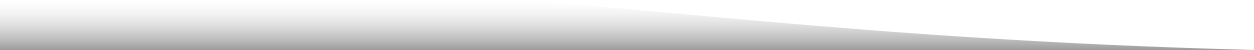

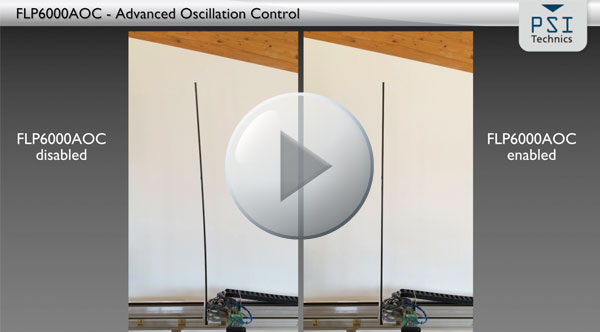

PSI Technics has developed FLP6000AOC (Advanced Oscillation Control) – a control system of ARATEC to decrease mast oscillations of stacker cranes in high-bay warehouses.

FLP6000AOC is a control system integrated into the intelligent ARATEC Positioning Solution System. The FLP6000AOC reduces mast oscillations of even highly dynamic stacker cranes to a minimum.

The FLP6000AOC significantly reduces mechanical stresses and the cycle time of stacker cranes and helps you to increase the throughput and lifespan of your high-bay warehouse or automated storage and retrieval system.

PSI Technics’ Advanced Oscillation Control (AOC) removes 89% of stacker crane mast vibrations and helps you to shorten cycle times, maintenance costs and increase productivity.

Modernization of High-Bay Warehouses

Volkswagen AG decided to retrofit their vehicle body warehouse in Wolfsburg, Germany, and chose PSI Technics’ ARATEC as a replacement for their existing ICS5000 positioning systems. ARATEC is an efficient, reliable system that easily integrates into the existing warehouse infrastructure.

Sensor Protection Cases

The innovative Thermo Protection Cooling Case (TPCC) ideally protects sensitive optical sensors, such as laser distance sensors or optical data transfer systems, from extreme heat (up to 176°F [+80°C]) and cold (down to -40°F [-40°C]) or extreme temperature variations in production and logistics facilities.

ARATEC® TPCC® - Registered in U.S. Patent and Trademark Office

Understand. Challenge the status quo. Consistently move forward: This is our vision of progress. We are advancing digitalization and we are leveraging existing data to create added value for our customers.

AUTOMATE. OPTIMIZE. INCREASE QUALITY. SAVE ENERGY.

Immerse yourself in the world of PSI Technics, the competence center for digitalization and automation. We accompany your technical and industrial processes into the future.

You can also use our contact form to make an appointment for an individually guided tour. Click here to visit our digital showroom

From March 21, 2022, you will find us at our new address An der Steinkaul 6a, 56333 Winningen in the industrial and business park "Am Flugplatz". Watch the highlights of the new company building

As image processing experts, we develop custom system solutions for challenging processes, e. g. for the Food Industry - Watch movie for Railway Transport and Logistics - Watch movie for the Automotive Industry - Watch movie for the Raw Materials / Commodities Industry - Watch movie

Designed for the continuous monitoring and visual quality control of production processes.

PSI Technics offers easy-to-use, application-specific digital image processing solutions that are designed for the continuous monitoring and quality control of production processes. Nearly all monitoring and measuring tasks can be automated by means of industrial image processing. Watch movie

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.Watch movie

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market: For STACKER CRANE applicationsFor BRIDGE CRANE applications

PSI Technics' ARATEC Positioning Solution System is an innovative and advanced solution for industrial positioning applications. Watch movie

The ARATEC's FLP6000AOC software reduces mast oscillations – even of highly dynamic stacker cranes – to a minimum. The test setup shows that the ARATEC Positioning Solution System with enabled FLP6000AOC compensates for mast oscillations in near-real time, even when the oscillations are caused by external disturbances.

You've got questions, requests or comments about our products and services? Contact our service team and receive a non-binding consultation.

PSI Technics GmbH

An der Steinkaul 6a

56333 Winningen | Germany

PHONE +49 (0) 2630 91590-0

FAX +49 (0) 2630 91590-99

info@psi-technics.com