The Conveyor Technology Planning department at Volkswagen AG, headquartered in Wolfsburg, Germany, had commissioned PSI Technics to analyze and evaluate the operation of a vertical material lift in a vehicle body warehouse. The successful cooperation was aimed at developing a new positioning standard for similar vertical lifting systems.

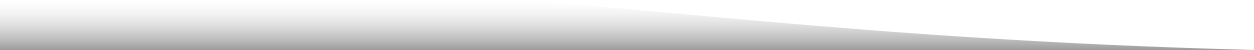

During the course of the project, a software simulation of the vertical lifting system was created using a finite element model (FE). Subsequently, a co-simulation interface was established to simulation of the system controlled by the ARATEC Positioning Solution System. The configuration enabled a detailed evaluation of the system's travel profile and resulting mechanical stresses affecting the system structure.

By using virtual modeling PSI Technics was able to create an ideal modernization concept for the vertical lifting system. The simulation showed that a modernization of the existing control interface with the ARATEC Positioning Solution System would result in considerably reduced mechanical stress. Virtual modeling revealed that mechanical stresses that are affecting critical system components can be reduced by approximately 10%.

Stress Comparison between the PLC-controlled System (blue) and a System with Positioning Control (red). Positioning control, improved drive technology and improvements to the loading and retrieval cycles will reduce peak mechanical stresses by approximately 10%.

Based on the optimization results, the client decided to replace his existing positioning solution. The existing controller was replaced by an extended ARATEC Positioning Solution System with closed-loop control. Instead of bus communication, the ARATEC system uses the lifting system's hardware signals (limit switches, position switches) as well as digital signals transmitted by the PLC. No changes to the existing S5 PLC were required.

In addition, the ARATEC system was installed parallel to the existing system to include redundancy as the lifting system is critical for production and to ensure the operator could switch between both systems if needed.

The optimization potential demonstrated by the simulation could be fully realized. Due to the optimized travel profile, creeping speed was completely eliminated and replaced by a controlled slow-down that enabled the system to reach the target positions faster. This meant that the acceleration of the actual system could be lowered by 16% to reduce system wear. Compared to the PLC-controlled system, realized time-savings of 3 seconds per motion sequence (down and back) were achieved with the ARATEC Positioning Solution System. Since the acceleration is proportional to the mechanical stresses, reduced mechanical stress can be expected and will be verified using strain gauges at run-time.

The system installed by PSI Technics has been successfully used in production since summer 2013.

Learn more about the benefits of PSI Technics' virtual modeling.

Click here to download our application reports.

ARATEC® TPCC® - Registered in U.S. Patent and Trademark Office

Understand. Challenge the status quo. Consistently move forward: This is our vision of progress. We are advancing digitalization and we are leveraging existing data to create added value for our customers.

AUTOMATE. OPTIMIZE. INCREASE QUALITY. SAVE ENERGY.

Immerse yourself in the world of PSI Technics, the competence center for digitalization and automation. We accompany your technical and industrial processes into the future.

You can also use our contact form to make an appointment for an individually guided tour. Click here to visit our digital showroom

From March 21, 2022, you will find us at our new address An der Steinkaul 6a, 56333 Winningen in the industrial and business park "Am Flugplatz". Watch the highlights of the new company building

As image processing experts, we develop custom system solutions for challenging processes, e. g. for the Food Industry - Watch movie for Railway Transport and Logistics - Watch movie for the Automotive Industry - Watch movie for the Raw Materials / Commodities Industry - Watch movie

Designed for the continuous monitoring and visual quality control of production processes.

PSI Technics offers easy-to-use, application-specific digital image processing solutions that are designed for the continuous monitoring and quality control of production processes. Nearly all monitoring and measuring tasks can be automated by means of industrial image processing. Watch movie

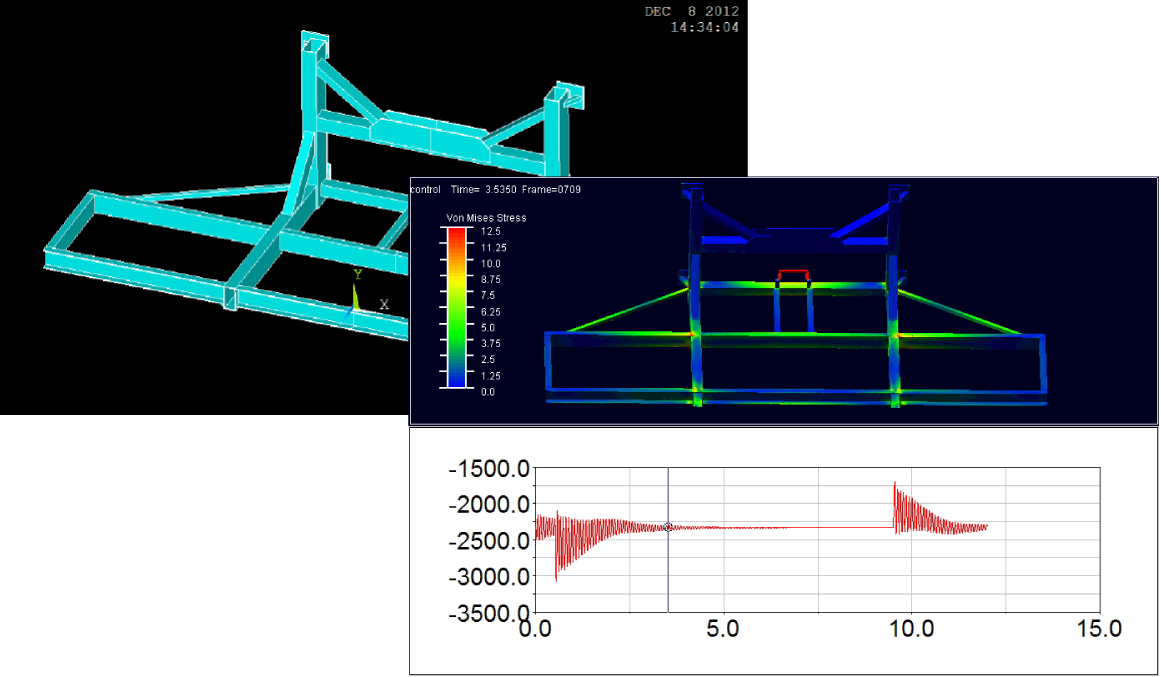

PSI Technics' ARATEC Positioning Solution System is an innovative solution for industrial positioning applications.Watch movie

We invite you to experience a completely new type of control technology – in an entertaining short story. A clear and straightforward presentation will show you why the ARATEC is the best positioning solution on the market: For STACKER CRANE applicationsFor BRIDGE CRANE applications

PSI Technics' ARATEC Positioning Solution System is an innovative and advanced solution for industrial positioning applications. Watch movie

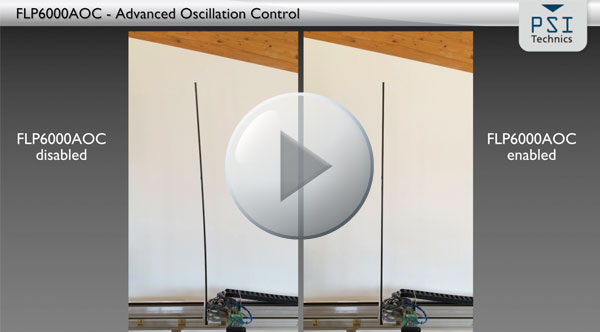

The ARATEC's FLP6000AOC software reduces mast oscillations – even of highly dynamic stacker cranes – to a minimum. The test setup shows that the ARATEC Positioning Solution System with enabled FLP6000AOC compensates for mast oscillations in near-real time, even when the oscillations are caused by external disturbances.

You've got questions, requests or comments about our products and services? Contact our service team and receive a non-binding consultation.

PSI Technics GmbH

An der Steinkaul 6a

56333 Winningen | Germany

PHONE +49 (0) 2630 91590-0

FAX +49 (0) 2630 91590-99

info@psi-technics.com